Introduction: Why Mono-Materials Are Changing Packaging Forever

Every day, we rely on packaging — from water bottles and food wraps to snack packets and cosmetic tubes. But after serving their purpose, where do these materials end up? Too often, they are dumped into landfills, washed into oceans, or incinerated into the atmosphere — causing severe pollution and damaging ecosystems worldwide.

Packaging plays a crucial role in preserving the quality and safety of products, from food items to liquids. However, its disposal presents a major environmental challenge. To tackle this, countries like Germany, Japan, the Netherlands, the United States, and India are leading the charge by developing sustainable packaging solutions aimed at protecting our planet for future generations.

Traditional multi-layered packaging, while effective in protection, poses challenges in recycling due to the combination of different materials. This is where mono-material packaging emerges as a game-changer, offering a sustainable alternative that aligns with the principles of a circular economy.

Mono-material packaging—made from a single type of polymer—is especially useful in applications such as food wrapping, beverage containers, and personal care products, allowing easier recycling, better sorting in waste streams, and lower environmental impact. It enhances packaging recyclability without compromising on barrier properties or product safety, making it a crucial innovation in the journey toward zero-waste packaging systems.

Signicent supports this transition by offering in-depth market assessment and valuation, helping clients identify growth opportunities, forecast trends, and evaluate the commercial potential of mono-material solutions across various industries.

What is Mono-Material Packaging? Why Is It the Future?

Mono-material packaging is exactly what it sounds like—packaging made entirely from a single type of material. Unlike conventional packaging, which often combines layers of plastics, aluminum, paper, and other components, mono-material solutions simplify the recycling process. By streamlining material recovery and reducing contamination, this innovation significantly improves recyclability and lessens environmental impact—emerging as a beacon of hope for truly sustainable packaging systems.

Instead of the complex and time-consuming process of separating mixed materials during recycling, mono-material packaging enables seamless processing. This results in higher-quality recycled materials that can be efficiently reintegrated into production cycles.

Benefits vs Multi-layer Packaging:

Mono-material packaging uses only one type of material (like 100% polyethylene or 100% polypropylene) instead of mixing layers like metal, plastic, and paper.

This makes recycling easy, cheap, and environment-friendly.

Protection: Shields against moisture, oxygen, and contamination.

Storage: Can be safely stored in varying temperatures.

Performance: Matches or even beats multi-layer packaging efficiency.

Consumer POV:Consumers today care deeply about sustainable choices — mono-material packaging enhances brand trust, drives loyalty, promotes eco-consciousness, and reflects a brand’s commitment to social responsibility.

Mono-Material vs Multi-Layer Packaging

| Feature | Mono-Material Packaging | Multi-Layer Packaging |

| Recyclability | High (up to 90%) | Very low (often below 20%) |

| Barrier Properties | Improving with specialized eco-coatings | Excellent, achieved through complex layering |

| Cost Efficiency | Moderate (simpler manufacturing and sorting) | High cost (material diversity and processing complexity) |

| Environmental Impact | Positive (supports sustainable waste management) | Negative (landfill and incineration burden) |

| Government Compliance | Easy (meets recycling regulations and targets) | Difficult (misaligned with circular economy goals) |

| Circularity | Supports closed-loop recycling systems | Typically results in downcycling or waste |

Why Mono-Material Packaging Matters

In today’s marketplace, consumers are not just purchasing products; they are supporting brands that reflect their values. Packaging has become a crucial factor in shaping a brand’s image. With Technology Scouting unlocking access to cutting-edge material innovations, mono-material packaging stands out as a game-changer—offering several environmental benefits that resonate with eco-conscious consumers.

These are several strong reasons why mono-material packaging is gaining traction:

- Simplified Recycling: Recycling facilities can easily sort and process single-material packages.

- Increased Recycling Efficiency: Without the need for material separation, recycling becomes faster and less energy-intensive.

- Reduced Energy Consumption: Both production and recycling of mono-material packaging consume less energy compared to multi-material systems.

- Circular Economy Promotion: Easier recycling encourages reuse, closing the loop on resource consumption.

- Enhanced Sustainability: By minimizing landfill waste and resource depletion, mono-material packaging becomes a strong ally in responsible packaging.

Types of Mono-Material Packaging

Innovation is pushing boundaries across material types. Here are key examples:

- Polyethylene (PE) and Polypropylene (PP) Packaging:

These plastics are favored for their strength, flexibility, and recyclability. They are increasingly used for pouches, wraps, and rigid containers. - Regenerated Cellulose Fiber (RCF) Packaging:

A biodegradable alternative derived from natural fibers, offering strong sustainability credentials without compromising functionality. - Mono-Oriented Polyethylene (MOPE):

Using Machine Direction Orientation (MDO) techniques, MOPE films improve durability and recyclability without mixing materials, enhancing both product protection and end-of-life recovery.

Why Mono-Material Packaging Matters for Your Brand

In order to reduce environmental effects, increase brand loyalty, and match with global movements towards recyclable solutions, packaging design for a circular economy strikes a balance between sustainability, performance, and perception.

| Feature | Mono-Material Packaging | Multi-Material Packaging |

| Barrier Coatings | High (with new tech) | Very High |

| Temperature Resistance | Excellent | Good |

| Recyclability | Easy and Economical | Difficult, Expensive |

| Supply Chain Simplicity | Simple | Complex |

| Shelf-Life Protection | Improving with Innovations | Established |

| Brand Perception | Eco-Friendly, Modern | Traditional, Polluting |

| Cost | Reducing with Tech Advancements | High due to complex materials |

| Example | 100% PE Pouches for Snacks | Foil-Laminated Pouches (Non-Recyclable) |

| Global Adoption | 🌍 EU, US, Japan leading | 📉 Phasing out due to bans |

Current Major Drawbacks in Traditional Packaging

Today’s packaging struggles with many problems, such as the use of harmful chemicals, poor barrier innovations, recyclability issues, temperature vulnerability, and storage concerns. These challenges are being mapped and tackled more strategically through Patent Landscape Analysis, helping brands identify technology gaps, emerging trends, and competitive innovations to build future-ready, sustainable packaging solutions.

- Harmful Chemicals: Many packaging materials still contain dangerous substances like heavy metals, solvents, and plasticizers that pose risks to both human health and the environment.

- Poor Barrier Innovations: There is a lack of eco-safe and effective barrier technologies, leaving products vulnerable to contamination and environmental factors.

- Recyclability Issues: Multi-layered packaging is difficult to recycle, contributing to an increase in waste and environmental pollution.

- Temperature Vulnerability: Many packaging types cannot withstand extreme temperature variations, risking product integrity and quality.

- Storage Concerns: Traditional packaging often leads to a rapid loss of product quality over time, affecting shelf life and consumer experience.

These challenges highlight the significant issues both industries and consumers face, including:

- Health Risks: Chemicals leaching from packaging materials can lead to serious health concerns for consumers.

- Carbon Footprint: Improper disposal of packaging contributes to a higher carbon footprint, worsening environmental challenges.

- Regulatory Compliance: Meeting global regulatory frameworks, such as Extended Producer Responsibility (EPR), has become increasingly difficult for manufacturers.

Packaging Industry Drawbacks:

- Harmful Chemicals in Barrier Coatings: Materials like PVDC and EVOH hinder the recyclability of packaging, adding to the environmental burden.

- Overuse of Aluminum Layers: The excessive use of aluminum layers makes packaging energy-intensive and harder to recycle.

- Shelf-Life and Temperature Issues: Reduced barrier complexity in packaging can result in inconsistent shelf-life, especially when exposed to temperature extremes.

Addressing Barrier Property Challenges

A Major Innovation Area:

The packaging industry is shifting towards high-barrier mono-materials, designed to protect products from oxygen, UV rays, moisture, and contamination. This innovation not only ensures product integrity but also supports a more sustainable future. Interestingly, similar to how Biological Sequence Search identifies patterns and optimizes outcomes in genomics, material scientists are now using data-driven methods to identify optimal formulations for recyclable barriers.

To further enhance sustainability, bio-coatings and cutting-edge nanotechnology are replacing harmful petrochemicals. These advanced solutions extend product shelf life while ensuring that packaging remains 100% recyclable, contributing to a healthier planet.

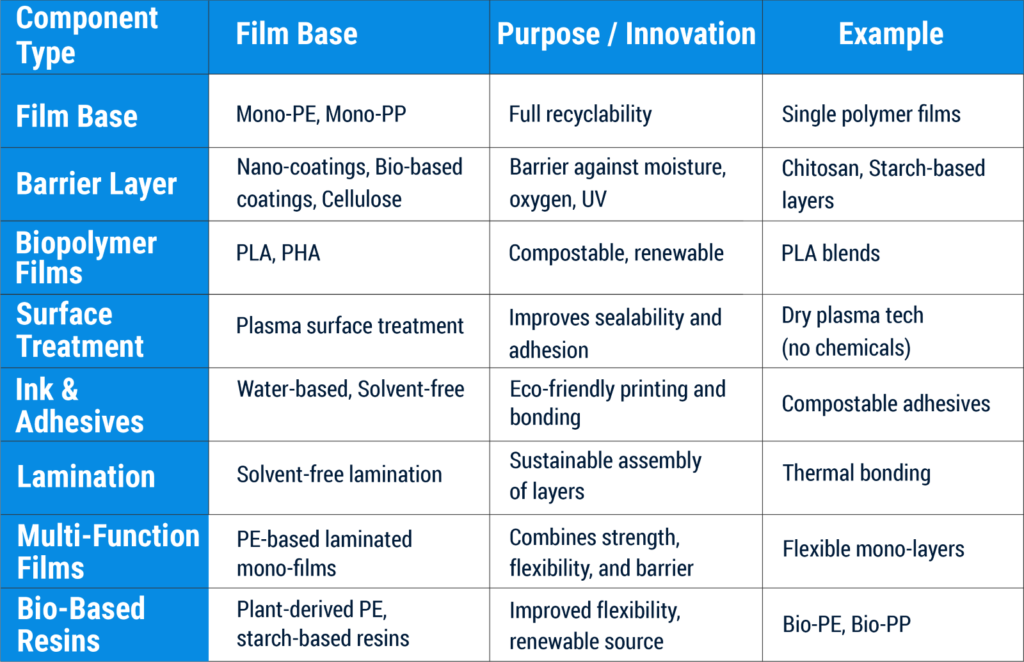

Technologies Behind Mono-Materials

To enable sustainable packaging, several innovative technologies and materials are now being integrated at every layer—from films and resins to coatings and adhesives.

Innovations in Mono-Material Packaging

Natural Coatings

Researchers have developed water-based polymer and nanocomposite thin films that provide excellent barrier properties, making mono-material packaging more effective in preserving product quality.

Mushroom-Based Packaging

Companies like Ecovative Design are pioneering the use of mycelium (mushroom roots) to create biodegradable packaging materials, offering a sustainable alternative to traditional packaging.

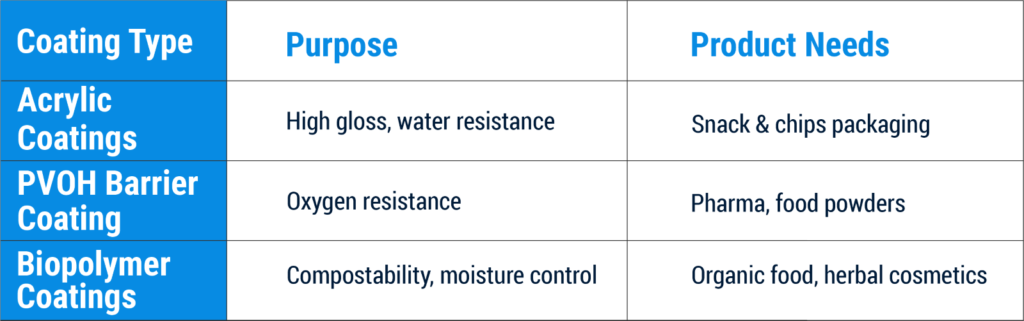

Common Coatings Used

Real-World Examples: How Brands Are Leading the Shift

Global brands are actively transitioning to mono-material packaging, showcasing real-world commitment to sustainability without compromising performance. In this journey, Patent Invalidity Search plays a critical role by ensuring that innovations in packaging design and materials do not infringe on existing patents—thus empowering brands to scale responsibly and legally.

- Nestlé is piloting mono-material flexible packaging for baby food, aiming to replace multi-layer laminates and simplify recyclability.

- Unilever is adopting PE-based mono-material pouches for shampoos and soaps, aligning with their circular economy targets.

- Amcor has launched the “AmLite” range—high-performance, fully recyclable mono-material packaging solutions addressing multiple industry needs.

Sector-Specific Use Cases: Where Mono-Materials Are Making a Difference

Certain industries demand high-barrier performance, and mono-materials are now evolving to meet these needs:

- Pharmaceuticals: Require ultra-barrier protection against oxygen and moisture. Companies like Huhtamaki and UFlex are innovating with push-tab mono-polymer blister packs and high-barrier mono-materials for liquid medications and condiments.

- Cosmetics: Shelf life and product stability are critical. While Triplex Laminates are still common, Berry Global and Constantia Flexibles are bridging the performance gap with recyclable PE-based films and EcoLam laminates.

Applications of Mono-Material Packaging

Mono-material packaging is transforming multiple industries by offering recyclable, efficient, and sustainable alternatives without compromising performance. At Signicent, we ensure that your innovations stay ahead through a Freedom To Operate (FTO) Search, helping companies avoid infringement risks while deploying novel mono-material solutions confidently in global markets.

Below is a breakdown of where and how these solutions are making a real-world impact across key sectors:

| Format | Sector | Application | Key Benefits |

| Sachets | Food, FMCG | Coffee, condiments, sugar | Freshness preservation + easy recyclability |

| Stand-Up Pouches (Doypacks) | Food, Pet Care, Household | Pet food, snacks, detergent pods | Brand appeal + space-saving + environmental gain |

| Rollstock | Food, Pharma | High-speed wrapping, blister packs | Efficient filling + material reduction + recyclability |

| Bottles & Containers | Personal Care, Cosmetics | Shampoos, lotions, creams | Sleek design + improved recycling stream |

| Tubes | Cosmetics, Pharma | Toothpaste, gels | Consistent barrier + single polymer use |

| Trays | Ready-to-Eat Meals, Retail | Pre-packed meals, cold cuts | Rigid support + mono-material film sealing |

Market Outlook for Mono-Material Flexible Packaging

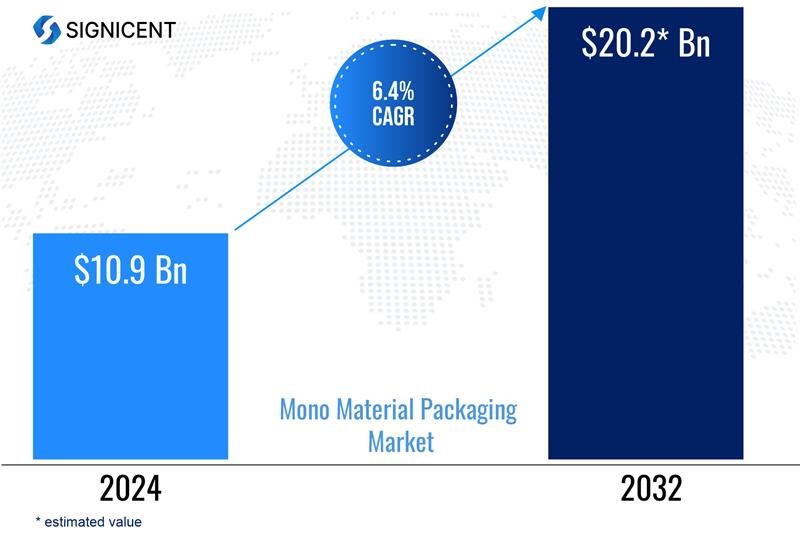

The mono-material packaging market is experiencing dynamic growth, propelled by increasing sustainability mandates, consumer demand for recyclable solutions, and innovations in packaging technologies across food, personal care, and pharmaceutical sectors.

According to Signicent Market Research, the global mono-material packaging market is projected to expand substantially, driven by circular economy goals, regulatory pressures like EPR, and the adoption of high-barrier, fully recyclable mono-materials across key industries.

Mono-Material Packaging Market Trends

According to a report by Signicent Market Intelligence, the global demand for mono-material packaging is projected to grow sharply in the coming years, fueled by:

- Brand Sustainability Goals targeting 2025 and 2030 milestones.

- Consumer activism is pressuring companies to offer greener products.

- Government regulations banning or taxing hard-to-recycle packaging formats.

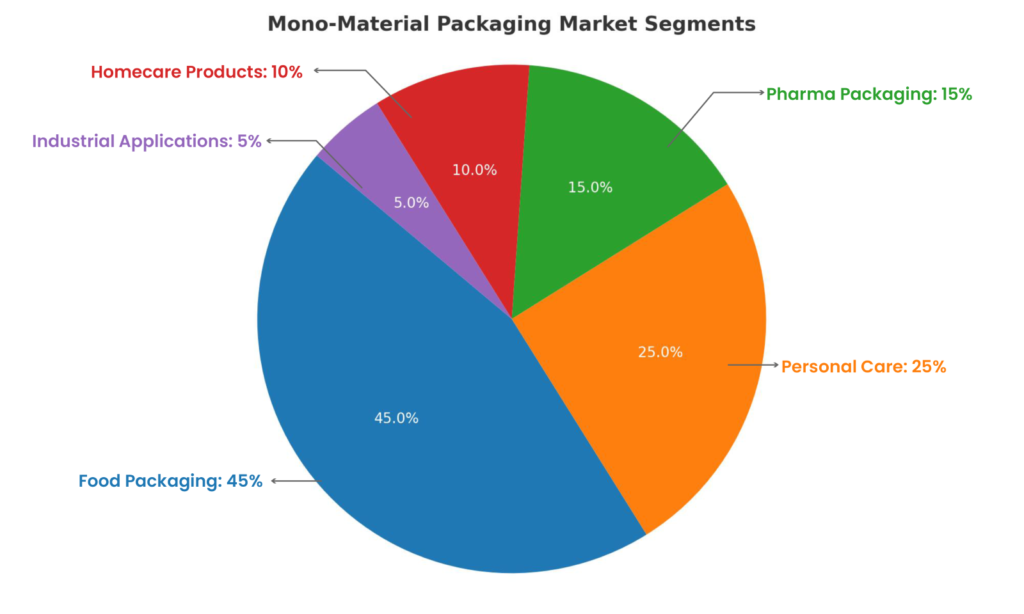

Market Segments: Splitting by Category

The pie chart below presents the confirmed distribution of mono-material packaging across various industry sectors, offering a visual breakdown of where this sustainable solution is being most actively adopted and making the greatest impact.

Key Players and Unique Innovations

As mono-material packaging gains global momentum, several industry leaders are setting benchmarks through pioneering technologies. Each of these companies is contributing unique innovations that not only enhance recyclability but also maintain or elevate performance. Let’s explore how these key players are shaping the sustainable packaging revolution.

| Company | Unique Innovation |

| Amcor | AmLite recyclable high-barrier films and pouches |

| Mondi Group | Paper-based and BarrierPack recyclable mono-material pouches |

| Huhtamaki | Push-tab mono-polymer blister packs and frozen food mono-solutions |

| Constantia Flexibles | EcoLam high-barrier mono-material laminates and films |

| Berry Global | PE-based sustainable and reinforced recyclable mono-material films |

| Sealed Air | High-performance reinforced mono-material packaging films |

| UFlex | High-barrier mono-material solutions for condiments and sauces |

| ePac Flexible Packaging | Digitally printed recyclable mono-material flexible packaging |

| DIC Corporation | Barrier coatings and inks optimized for mono-material sustainability |

| Ecovative Design | Mycelium-based eco-friendly mono-material packaging alternatives |

How Signicent Transforms Clients’ Needs in Sustainable Packaging

From concept to compliance, Signicent helps businesses to lead the green packaging revolution with insights, innovation, and intelligent strategies designed for the future.

- Technology Landscape Analysis for Sustainable Materials

- Scouting for barrier coating innovations

- Customized market research for packaging clients

- Circular economy solutions design

- Regulatory and compliance research (EPR, Plastics Directives)

✅ Helping clients transition from multi-layer to mono-material packaging efficiently and innovatively.

✅ Supporting companies to capture sustainability-focused consumers while meeting industry and government standards.

If you’re looking for cutting-edge technology solutions and industry insights, Signicent is here to help. We specialize in White Space Analysis and Technology Gap Assessment, which identify potential for innovation and growth. Our experience also offers problem-solving research help, which ensures that firms develop sustainable and efficient solutions that are adapted to their specific requirements.

Future Outlook: Impact on Market and Products

The global packaging industry is set for a major transformation as governments enforce stricter Extended Producer Responsibility (EPR) regulations by 2026. These mandates are accelerating the shift towards sustainable solutions, with mono-material packaging at the forefront. Industries are actively replacing traditional multi-layer plastics with recyclable and bio-based alternatives to comply with these emerging policies and reduce environmental impact.

Looking ahead, the food and personal care sectors are expected to witness the highest growth in mono-material adoption. Innovation in barrier coatings, bio-resins, and nanotechnology will further enhance packaging performance—offering superior protection without compromising recyclability. As consumer demand and legislative pressure align, mono-material packaging will redefine how products are protected, presented, and preserved in the future.

FAQs: Your Guide to Mono-Material Packaging with Signicent

Q1. Why should I switch to mono-material packaging now?

👉 To stay ahead of evolving regulations like EPR and build a sustainable brand. Signicent helps future-proof your packaging strategy with innovative solutions.

Q2. Can mono-materials match the protection level of multi-layer materials?

👉 Yes. With advanced coatings and plasma technologies, Signicent scouts’ solutions that match or exceed traditional barrier performance.

Q3. Is mono-material packaging cost-effective for long-term use?

👉 Absolutely. Signicent’s custom market research identifies recyclable options that cut waste management costs and streamline supply chains.

Q4. What industries benefit most from mono-material packaging?

👉 Sectors like food, personal care, pharma, and e-commerce see major advantages. Signicent offers tailored tech scouting for your industry.

Q5. What are the biggest challenges in switching to mono-materials?

👉 Performance gaps and production changes. Signicent solves this through landscape studies and material-performance benchmarking for smooth transitions.

Q6. How does mono-material packaging support environmental goals?

👉 It reduces landfill waste and simplifies recycling. Signicent identifies bio-based and recyclable materials to boost your ESG compliance.

Q7. How does Signicent support your mono-material journey?

👉 From technology scouting and regulatory research to circular economy strategies—Signicent is your end-to-end innovation partner.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Patent Landscape

- Patent Portfolio Analysis

- Patent Invalidity Search

- Patent Licensing Services

- Freedom to operate (FTO)

- Chemical Structure Search

- Design Patent Search

- Technology Scouting

- Technology Landscape Analysis

- Technology gap analysis

- Technology Intelligence

- Market Research

- Bio Sequence Search

Elevate your Innovation and Research with Signicent’s cutting-edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.