Sustainable Packaging in Laundry and Homecare is showing growth. This report will shed light on challenges, solutions, recent technology advancements, patents & research in the area of Sustainable Packaging in Laundry and Homecare. Get a free primer here.

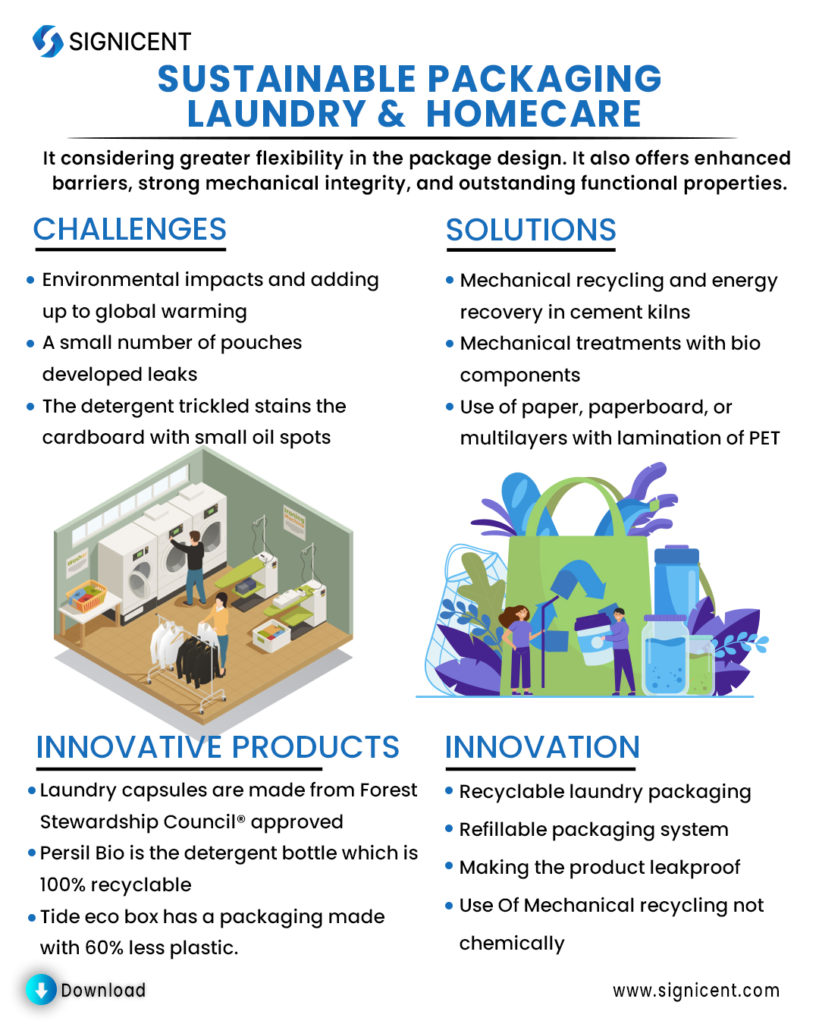

Today, the packaging industry is undergoing unparalleled transformation. Sustainable packaging in laundry and home care is considering greater flexibility in the package design. The packaging helps in shaping aesthetic appeal. It also offers enhanced barriers, strong mechanical integrity, and outstanding functional properties.

Reduce, Reuse, Recycle – these three ‘R’s can make a revolutionary change. It is an important part of sustainable living, as sustainable packaging help to cut down on the amount of waste. Innovative methods are incorporated in producing sustainable packaging material that is extremely cost-efficient as compared to traditional methods. This technical article will summarize most of the technologies, processes, and innovations happening to find alternatives to conventional packaging materials.

Virgin Plastic alternatives for Sustainable Packaging

- Seed infused packaging: A form of biodegradable packaging is made with seeds embedded in the material, allowing consumers to bury the product container in the ground.

- Seaweed-based packaging: Seaweed is an affordable source of polysaccharide biomass. When seaweed films are incorporated with microcrystalline cellulose, the thermal stability of packaging is enhanced.

- Plant-based mushrooms: Mushroom packaging is an environment-friendly alternative to Styrofoam. Unlike Styrofoam, it consists of 100 percent biodegradable material that can be recycled directly in and by nature.

- Use of bio-plastics: Bioplastics are plastic materials produced from renewable biomass sources, such as vegetable fats and oils, corn starch, straw, woodchips, sawdust, etc.

- Use of milk protein: An alternative packaging made from biodegradable materials derived from organic sources such as wood pulp and waste milk.

Innovative Products in Laundry and Homecare Packaging

- Laundry capsules: Plastic-free packaging with child-lock closure designed to keep capsules safe in their journey and to take minimum space in the cupboard. The Packaging is made from Forest Stewardship Council® approved, sustainable materials and is 100% recyclable too. It is 100% Plastic-free Packaging.

- Persil Bio: The detergent bottle is 100% recyclable and contains recycled plastic, reducing plastic use, detergent is plant-based. It is 100% recyclable bottles.

- Tide eco box: Packaging made with 60% less plastic, Formula is made with 100% renewable wind power electricity, made with 30% less water.

- Zero Plastic Laundry Detergent: Packaged in reusable canisters made from steel, the world’s most recycled and recyclable material, water-activated, fully biodegradable powders, and powder tablets.

Technology Innovation in Laundry and Homecare Packaging

Recyclable laundry packaging : Fully recyclable laundry packaging for the laundry pods. INNATE™ TF Polyethylene Resins for Tenter Frame Biaxial Orientation (TF-BOPE) has been chosen by Liby for packaging.

Refillable packaging system: Allowing to buy as much needed in reusable containers and finally recycles all packaging at the end of its life, meet consumer demand for home refill of Unilever’s laundry and cleaning products.

Open Innovation & Academic Research

Massachusetts Institute of Technology, USA : High impact opportunity areas include alignment amongst all key stakeholders. Massachusetts Institute of Technology has been establishing standardized signage and labels, increasing consumer education, and tackling difficult-to-recycle materials through scaling up technology, enacting policy, providing materials alternatives with corresponding infrastructure, or redesigning packaging.

The University of Cambridge, England: The University of Cambridge spin-out’s major scientific breakthrough involves the development of single-use plastic made from every plant, such as peas. With the potential for everything from single-use bags to sachets, Xampla’s first product will be a natural ‘microcapsule’ to keep the fragrance fresh inside personal and home care products like fabric conditioner.

Technology Scouting

The traditional process causes a lot of challenges with conventional packaging, some of the common problems faced are as follows:

- The Chemical treatment of plastic packaging wastes usually leads to environmental impacts and adding up to global warming.

- A small number of pouches developed leaks. The detergent trickled and dribbled out of the containers, staining the cardboard with small oil spots.

Viable Solutions

Post comprehensive analysis of publicly and commercially available information, we came across the following finest solutions to overcome the aforementioned problems:

- PET, HDPE, LDPE, PP, and PS should not be recycled chemically to refinery feedstock or fuel products. It rather should be treated by Mechanical recycling and energy recovery in cement kilns. Further, mechanical treatments can include bio components.

- Use of paper, paperboard, or multilayers with lamination of PET. The heat sealing of the bag ensures the right moisture vapour transmission rate to make the product leakproof.

Signicent offers a comprehensive analysis and provides services in innovation management, research support via problem-solution approaches wherein helping technology specialists with their requirements of understanding novel & emerging technologies. Submit custom requirement here.

Mechanical Recycling of Plastic waste

RWTH Aachen University [Germany] : This reference discloses the development of a theoretical model for chemical recycling technologies for plastic packaging wastes. Further, it has been identified that some chemical processes are not environment friendly and hence PET, HDPE, LDPE, PP and PS should not be recycled chemically to refinery feedstock or fuel products and rather be treated by mechanical recycling and energy recovery in cement kilns in order to reduce global warming impacts.

Making the Packaging Water Resistant

RichColes Packaging Associates Limited, [UK]: This research unveils the use of paper and paperboard with lamination of PE, PP, or PET and heat sealing to make the product leakproof. Further, it specifies innovations like 100% biobased carton using bioplastics, such as bio- polyethylene (bio-PE) derived from sugar cane, and other applications of interests of bioplastics with paper and paperboard.

Multilayer Sustainable Packaging: Innovation and Sustainability

Multilayer packaging has gained popularity. Each layer has a critical role. For instance, the inner layer strongly seals, while the other layer protects from abrasion resistance and stiffness. The middle layer functions as an oxygen barrier (EVOH) and light (metalized layer).

- Glenroy (US) specializes in Multilayer flexible packaging in foods, beverages, cleaning agents, toiletries, beauty products, personal care, healthcare products.

- New Envi (Australia) is a packaging business that provides eco-friendly packaging solutions for homecare.

- BASF (Germany) supplies chemically recycled polyamide.

- Borealis (Austria) provides sustainably produced polyethylene.

Future of Sustainable Packaging

Consumers have become more conscious and are opting profoundly for eco-friendly packaging. The future is quite promising and will revolve around following aspects :

- Focus on customer safety, compliance, guidelines, and convenience.

- Smart Packaging and intelligent packaging

- Sustainable Packaging

- Anti-counterfeit packaging

- Innovations in packaging machinery/automation

Market Research Sustainable Packaging in Laundry and Homecare

The Home Care Packaging Market size was valued at USD 94.45 billion in 2019 and is anticipated to expand at a CAGR of 8.5% over the forecast period with a value of USD 160.96 billion by 2025.

The Sustainable Packaging Market size was valued at USD 168.3 billion in 2017 and is anticipated to expand at a CAGR of 6% over the forecast period with a value of USD 268.2 billion by 2025.