This report will shed light on challenges, solutions, recent technology advancements, patents & research in the area of Smart Beer – Beer Brewing with IoT & AI. Get a free primer or contact us for a custom report.

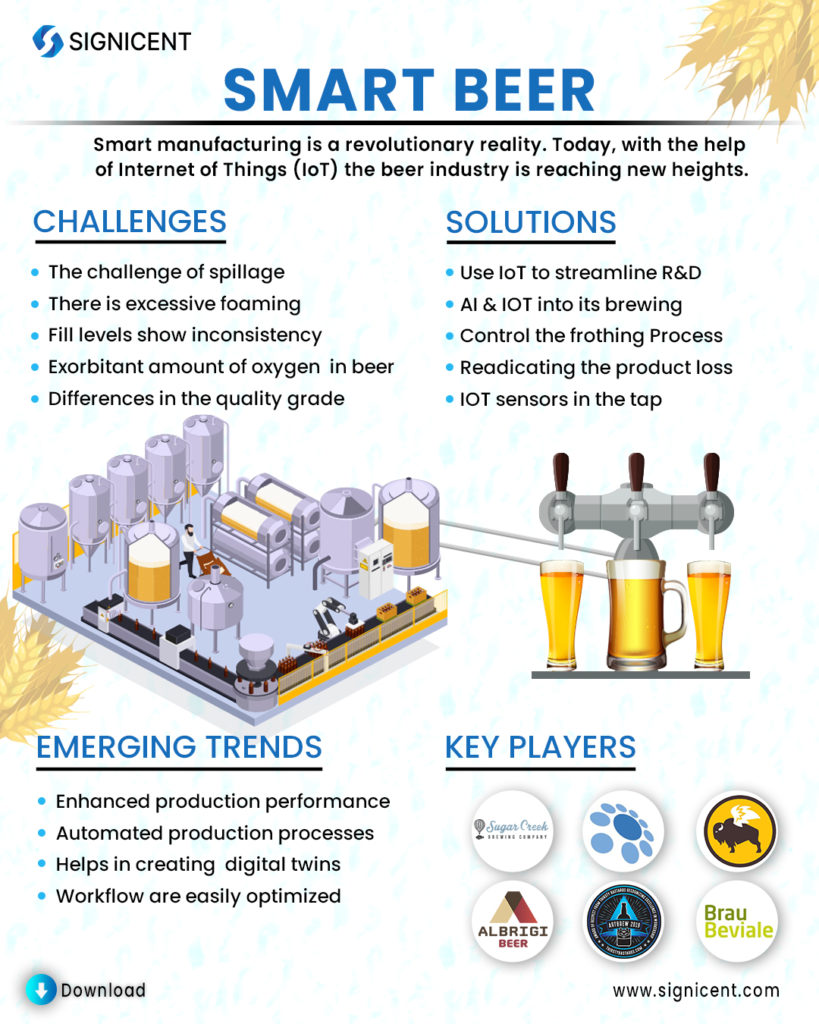

Smart manufacturing is a revolutionary reality. Today, with the help of Internet of Things (IoT) the beer industry is reaching new heights. Companies are becoming proactive from being reactive. These technologies have drastically enhanced production performance. Breweries are embracing IoT and AI to create more automated production processes. With the help of a smart manufacturing approach, it’s accomplishable to create digital twins of brewery products. Additionally, the production line and the entire workflow are easily optimized.

Use IoT to streamline R&D, optimize plans, improve the quality and quantity of Beer. This technology is promising in reducing product loss, improving agility as well.

Blending big data, the cloud, the digital twin with IoT can incline capacity, optimize resource utilization, and ramp up production which promotes innovation. To understand the industry challenges relating to the beer industry, we thoroughly investigated thousands of scientific literature, non-patent literature, patent- literature, available products, and recent inventions to figure out the major problem areas of concern.

Speaker Charles Nouwen (Anheuser-Busch InBev) talks about Innovations in beer industry in the light of ongoing accelerated trends with Lalit Kapur & Ravish Kumar (Signicent).

Charles Nouwen is a brewmaster from Belgium. As leader of the beer culture program for Anheuser-Busch InBev he now brings all of this together in an effort to elevate beer industry, the creativity, quality and craftmanship that goes into it.

Challenges with Smart Beer

The traditional process causes a lot of hindrance with Beer production, some of the common problems faced are as follows:

- The fill levels show inconsistency.

- There is excessive foaming.

- The challenge of spillage.

- The exorbitant amount of oxygen dissolved in the beer.

- Slight differences in the quality grade due to too much oxygen in the beer.

Post comprehensive analysis of publicly and commercially available information, we came across the following finest solutions to overcome these problems:

Solution in making Smart Beer

- Sugar Creek Brewing has amalgamated AI and IoT into its brewing process. This helped them in elevating the manufacturing and the quality of their beer manifolds. A camera is installed to capture photographs of the beer. It is then combined with data that is collected during bottling operations. This is then uploaded onto the cloud which is then interpreted by the algorithms.

- StapleBarn Ltd. Has developed Aletrim. It is a special kind of nozzle that controls the frothing process. It ensures that the perfect pint is made without spillage.

- Buffalo Wild Wings, a popular sports bar has adopted IoT technology. It helps in eradicating the product loss resulting due to bad pours. They have incorporated a system that monitors beer flow data through IoT sensors in the taps. Then, a comparison is made with real-time data and past records.

Beer Brewing with IoT: Smart Beer

- Hop is a volatile ingredient that must be incorporated into the brewing process within 12 hours of being harvested. IoT-enabled sensors can help in ensuring that they’re incorporated in peak conditions.

- Breweries are adopting IoT, AI, and machine learning, big data, edge computing, virtual reality (VR) and augmented reality (AR) to create more automated production processes.

- This embraces different departments, from product design, packaging, manufacturing, and QA to logistics.

- By using a smart manufacturing approach, it’s possible to create digital twins. Digital twins of brewery products, plants, and production lines help in simulating and optimizing the entire workflow.

- Smart Beer Membrane Filter (BMF) gathers data about the best time to clean the filter. And remove particles that clog it up.

- IoT sensors on packaging machines record changes in temperature or vibrations. It enables predictive maintenance and reduces downtime of the production line.

Companies Using IoT in Brewery

Albrlgi Beer SBS: The SBS (Smart Brewery System) presents characteristics of absolute excellence in quality of construction, in technology for self-management of mashing and wort boiling. In particular, the program harmonizes in a perfect way the processes of the involved enzymes (phytase, beta-glucasi, protease, beta-amylase, alpha-amylase) and the delicate activity concerning the final phase of mustment.

BrauBeviale SBS: International technology group, ANDRITZ, is presenting its unrivaled range of separation and filtration technologies for the beer industry at BrauBeviale in Nuremberg. Combining efficiency and ease of maintenance, ArtBREW is a high-quality and simple-to-operate beer clarification solution, which comes as a plug-and-play unit for the craft beer industry but also in large sizes for industrial beer production.

Start-ups Working on IoT in Brewery

Pubinno uses artificial intelligence-enabled taps to optimize many aspects of the beer serving experience. From controlling liquid flow to maintaining ideal temperatures, it claims to be “the future of draft beer. It minimizes waste and maintains the quality of beer from the brewery via its AI and Technology.

Brew Pipeline Inc. partners with craft breweries from across the U.S. to help expand their market reach and distribute to new areas. Brew Pipeline’s flagship initiative, called Guest Brewer allows craft brewers to sell award-winning craft beer for limited amounts of time to new-market consumers.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

Collaboration Among Companies and Universities

Reformation Brewery (2013, US) has partnered with Wander North Georgia (2016, US) to debut Nolan the Wanderer, a rotating IPA series. Nolan will have a unique malt, hop & process with each release- rotating through different styles, flavors, colors, techniques that make IPA a compelling and diverse beer. The recipe will be featuring notes of marmalade, grapefruit, and sap– perfect for sipping in spring.

Carlsberg launched plans for the project for designs of the world’s first paper beer bottle made with sustainable and recyclable wood fibers, working alongside EcoXpac, BillerudKorsnäs, and post-doctoral researchers from the Technical University of Denmark. This collaboration has resulted in the creation of the paper bottle company Paboco.

Mergers & Acquisitions (M&A)

- Heineken (1873, Netherlands) has acquired full ownership of London Brixton Brewery (2013, London). In 2017, investment from Heineken funded a purpose-built brewery and kept Brixton Brewery’s original railway arches site as a taproom and experimental brewery.

- Using Heineken, Brixton Brewery will continue to operate as a separate entity with the founders staying in charge of day-to-day management and creative direction.

- Heineken says it will help develop retail opportunities, support supply chain expertise, and facilitate collaborations.

Regulatory Guidelines

- Regulation (EU) 1169/2011 (EU 2011) on the provision of food information to consumers requires that the ‘actual alcoholic strength by volume’ labeling of an alcoholic beverage containing more than 1.2 % by volume of alcohol is given.

- CA Code Regs. 16, § 5716, A sample of edible cannabis products shall be deemed to have passed homogeneity testing. If the relative standard deviation exceeds plus or minus 10% cannot be released for retail sale.

- WA Admin. Code § 314-55-095, A single unit of marijuana concentrate in the marijuana-infused product cannot exceed 1 g.

- EU Directive 2010/13/EU on the coordination of laws and regulations concerning the provision of audiovisual media (the Audio-visual Media Services Directive (AVMSD)), sets out criteria that commercial communication (television advertising, teleshopping, sponsorship, and product placement) of alcohol and other commodities must comply with.

- Federal Alcohol Administration Act (27 U.S.C., Chapter 8, section 201-212) was enacted in 1935 to further protect the revenue derived from distilled spirits, wine, and malt beverages, to regulate interstate and foreign commerce.

- Wine is defined in FAA Act as containing not less than 7 and not more than 24 percent alcohol by volume [27 U.S.C. 211(a)(6)]. Malt beverage is defined as a beverage made by the alcoholic fermentation of specific materials [27 U.S.C. 211(a)(7)].

Recent Report

- Low Voltage Products Report: How innovations are overriding the challenges & market?

- Food Processing Technology Report: Can Technology Spark the Food Market?

- Water Treatment System Report: How Sustainability has Power to Drive Market?

- Virtual Protection Relay Report: What Market Trends Are Expected?

- Vegan Edible Collagen: How It Will Change Market & Eating Habits?