In today’s environmentally conscious technology landscape world, the food industry is constantly seeking innovative solutions to reduce waste and minimize the impact on the environment. One such solution gaining momentum is the use of edible food casings. These revolutionary packaging materials not only protect food products but are also designed to be consumed along with the food, offering a sustainable alternative to traditional packaging.

The edible food casing market has grown significantly. The technology scouting report on the edible food casings area revealed solutions to technical challenges, information on industry standards, key companies & market trends.

Types of Edible Food Casings:

Food casings are wraps that encase food, adding structure, protection, and flavor. Found in hot-dogs, cheese, candies, desserts and baked goods, they enhance appearance and increase shelf life. Each edible casing has a unique feel and flavor that enhances the pleasure of each bite and chew of the food you’re.

The two main types of casings are:

- Natural (meat/hot-dogs/bratwurst)

- Artificial (collagen)

Real-life Challenges:

Food casings, essential as they are, face various real-life challenges during the food-making process. Some of these challenges include:

- Tearing or Ripping: Casings can tear or rip during stuffing or twisting, especially if they are too dry or have any weak spots.

- Uneven Thickness: Inconsistent thickness across the casing can lead to uneven cooking or bursting during cooking.

- Brittleness: Casings that are too dry or have been stored improperly can become brittle, making them prone to cracking or breaking during handling.

- Flavor Transfer: Certain casings, especially artificial ones, may impart unwanted flavors to the food if not properly treated or if they meet strong-smelling ingredients.

- Storage Issues: Improper storage conditions, such as exposure to moisture or fluctuations in temperature, can cause casings to spoil or become unusable.

Additionally, there may be concerns regarding the taste, selection criteria, texture, and shelf life of products encased in edible casings.

Moreover, scaling up production to meet the demands of the market while maintaining quality standards poses another significant challenge.

Innovative Solutions:

In recent years, significant technological intelligence related innovations have been made in the edible food casing industry to address the aforementioned challenges.

Advancements in edible film technology:

In edible film technology, edible coatings are one of its components for protecting the surface of food products to enhance their quality, shelf life, and appearance.

Using edible coatings in edible casings provides a protective barrier around the food product.

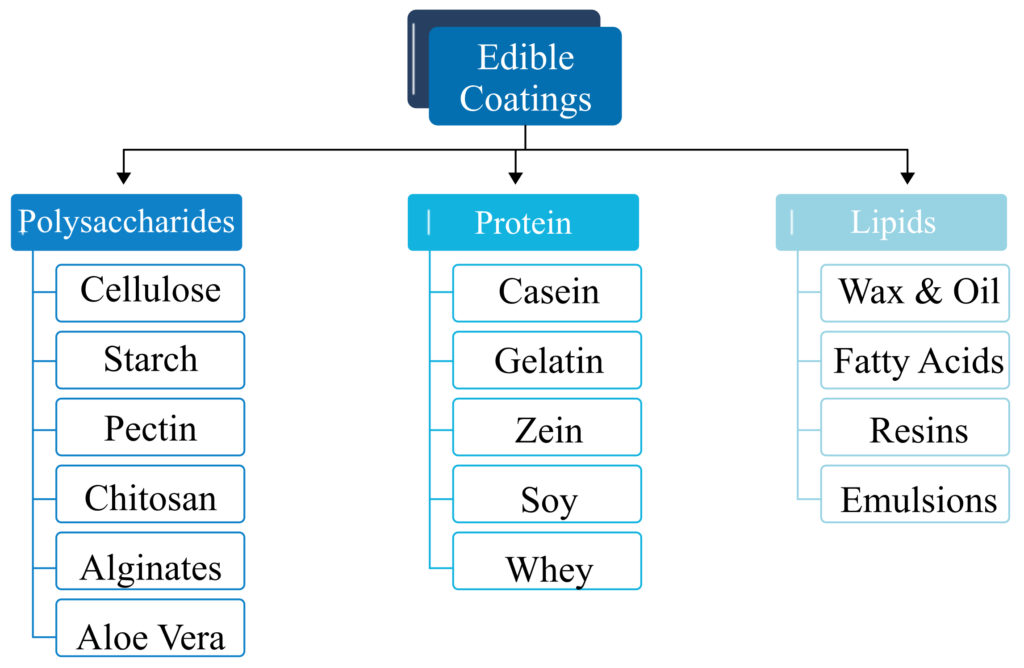

Generally, the edible food-coating materials are classified into three types such as polysaccharides, proteins and lipids.

Edible coatings can be formulated with various ingredients, including natural polymers, antioxidants, and antimicrobial agents, to provide specific functional properties.

Edible coatings extend shelf life, preserve freshness, and protect food from contaminants, reducing waste and enhancing safety.

They improve the appearance of food, provide functional benefits like added nutrients or flavorings, and contribute to overall consumer satisfaction.

Eco-friendly Alternatives:

Sustainable alternatives like biodegradable casings are gaining popularity in the food casing sector, offering eco-friendly solutions.

- Plant-based polymers (from corn, soybeans, or tapioca) offer biodegradable, eco-friendly alternatives, reducing reliance on animal-derived products.

- Alginate-based gels from seaweed offer biodegradability, non-toxicity, and superior barrier properties.

- Cellulose-based films from wood pulp or cotton linters provide transparency and strong barriers against moisture and oxygen.

- Pectin gels are derived from fruits and vegetables, particularly citrus fruits and apples.

- Agar gels are derived from seaweed and are commonly used as gelling agents in desserts, confectionery, and savory dishes.

These technology commercialization options meet consumer demand for eco-friendly products while promoting environmental stewardship in food production.

Importance of Casings:

Casings play a crucial role in food production for several reasons:

- Structure: Casings provide a form for the food product, helping it retain its shape during cooking and handling.

- Ease of Handling: They make it easier to package, transport, and store food products.

- Protection: Casings act as a barrier, protecting the food from external contaminants and preventing moisture loss during cooking and storage.

- Enhanced Flavor and Texture: Certain casings, like natural casings, impart unique flavors and textures to the food product, enhancing its overall quality.

Signicent’s actively participates in technology gap analysis to drive innovations in edible casing technology, enhancing durability, shelf-life extension, and barrier properties for improved food safety and quality.

Food Casings Market:

According to Signicent’s Market Intelligence, the global market for Edible food casings is expected to expand at a CAGR of 6.0% from US$ 1.74 Bn (approx.) in 2024 to reach a value of US$ 2.48 Bn by 2031 over the forecast period.

Industry Insights:

Some of the major food companies and their food casings, by category:

Hempler, Newyork style sausage company, Boars head, Zoe’s meat, Ever good and Tyson foods are actively working on Natural casings.

Hillshire farm, Silva sausage, Nippi and Nitta Gelatin produce Collagen based casings.

Viscofan Group, Devro, Viskase, Kalle and Selo Group Are working on Cellulose -based casings.

Key Players:

Some of the top food casings manufacturers:

- A pioneer in edible packaging solutions, WikiFoods specializes in producing edible food wrappers made from natural ingredients.

- MonoSol specializes in water-soluble film technology and has developed edible films that can be used as casings for various food products.

- Notpla is known for its seaweed-based packaging solutions, including edible sachets and casings.

- Tate & Lyle offers a range of edible coatings and films derived from renewable sources like starches and cellulose.

- Tipa Corp specializes in compostable packaging, offering edible coatings and films for diverse food applications.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Technology Intelligence

- Market Research

- Patent Landscape

- Technology gap analysis

- Design Patent Search

- Portfolio Analysis

- Freedom to operate

- Bio Sequence Search

- Innovation pipeline identification

- Chemical Structure Search

- Patent Invalidity Search

- Manufacturers Search/ Supplier search

- Patent Licensing Services

Elevate your Innovation and Research with Signicent’s cutting edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.