Consumers today are no longer just looking for fresh food—they care about how it’s packaged too. Safety, sustainability, and trust are now non-negotiables. But if we look around, the shelves are still packed with plastic wraps, laminated paper, and heavy glass jars. And honestly, each of these brings its own set of headaches—from recyclability issues to carbon-heavy transport.

While traditional materials are starting to feel outdated, foil packaging is quietly stepping up. It’s lightweight, offers strong barrier properties, and even has the potential for recyclability. But here’s the twist—it can do a lot more when innovation meets intention.

That’s where technology Gap Analysis plays a major role. It helps brands uncover opportunities in Mono materials, smart sealing systems, compostable layers, and digital finishes. The goal? To design packaging that not only protects products but also respects the planet—and keeps up with evolving consumer and regulatory demands.

Can foil preserve freshness better than other materials?

Yes, foil wrapping stands out when it comes to maintaining freshness, especially in harsh situations. Unlike plastics, which can leach chemicals, and paper, which absorbs moisture, foil acts as a robust barrier to air, light, and pollutants. It protects fragile objects, prolonging shelf life while maintaining quality. Glass, while protective, is heavy and prone to breaking.

What makes foil attractive now is how it is evolving brands are increasingly looking into monomaterial foils, compostable coatings, and recyclable formats. It is no longer simply about packaging; it is about integrating performance and sustainability. Foil is proving to be one of the smartest packaging alternatives for consumers who want safe, fresh, and environmentally friendly products.

What Is Foil Packaging?

Foil packaging is made from ultra-thin aluminum layers, often combined with paper or plastic, acting as a strong barrier against moisture, oxygen, and light—ensuring freshness, safety, and longer shelf life for products.

Its key characteristics include:

- Barrier Strength: It acts like an invisible shield, guarding your product from oxygen, moisture, light, and odors that could ruin freshness.

- Flexibility: It adapts easily—whether you need wraps, sachets, lids, pouches, or even blister packs.

- Lightweight: It’s much lighter than bulky glass jars or metal cans, making it easier to ship and store.

- Printable Surface: You can add eye-catching graphics and metallic finishes that make the packaging pop on shelves.

- Tamper Evidence: Heat-sealed or peelable layers give consumers peace of mind that safety comes first.

In short, foil packaging blends protection, presentation, and performance—and in many cases, beats traditional packaging options hands down.

Everyday Applications of Foil Packaging

We often find plastic packaging in everything—from snacks to skincare and even dairy items. Yet as industries push for more safety and sustainability, foil packaging is emerging as a smarter alternative. It’s not only adaptable to diverse product types and storage conditions but also offers superior protection, longer shelf life, and reduced environmental impact. To confidently innovate in this space, companies rely on Patent Invalidity Analysis to challenge outdated patents and unlock room for breakthrough designs in foil-based solutions. This strategic insight helps brands adopt next-gen packaging technologies without legal risks—turning ideas into market-ready, IP-safe innovations.

Below are some real-life ways foil packaging fits seamlessly into our everyday routines:

| Industry | Examples of Foil Use |

| Food & Snacks | Chocolate wraps, coffee pouches, cheese and butter foil |

| Pharmaceuticals | Blister packs, sachet wrappers, foil-sealed lids |

| Personal Care | Sample sachets, foil caps for creams, cosmetic packs |

| Pet Food | Stand-up foil pouches with resealable zippers |

| Ready Meals | Foil lids for healthy microwaveable meals |

| Electronics/Industrial | Anti-static foil pouches, moisture-barrier packaging |

Consumer Challenges Before Foil Packaging

Before the arrival of modern foil solutions, consumers regularly faced a range of frustrating issues:

Traditional packaging materials couldn’t keep up with real-world needs—especially for food, pharma, and daily goods where freshness, safety, and durability truly matter.

- Food spoilage during shipping and storage

Food often spoiled before reaching your plate. Without reliable barrier protection, moisture and oxygen seeped in—degrading taste, nutrition, and shelf life. - Pharmaceuticals lost effectiveness

Light, humidity, and air exposure weakened sensitive drug formulations, making them less potent and compromising safety by the time they are consumed. - Inadequate protection from paper & plastic

Paper and plastic lacked multi-layer shielding. As a result, snacks went stale, fragile goods arrived damaged, and overall product integrity suffered. - Tamper detection was unreliable

Most conventional packaging lacked clear tamper-evident features, leaving consumers unsure if the product was safe, sealed, or previously opened. - Bulky packaging drove up delivery and retail costs

Heavier materials like glass or thick plastics increased shipping weight, raising prices and reducing sustainability in the supply chain.

Packaging Type Comparison

| Feature / Type | Foil Packaging | Plastic Packaging |

| Barrier Protection | Excellent oxygen, moisture, light resistance | Good to moderate; depends on polymer lamination |

| Flexibility | Highly flexible: wraps, pouches, lids | Flexible; some rigid options available |

| Sustainability | Recyclable monomaterial; energy‑intense production | Mixed recyclability; often down‑cycled |

| Cost | Moderate–high, depending on foil thickness | Generally low to moderate |

| Shelf-Life Extension | Superior—preserves freshness and active compounds | Good, but oxygen permeability may degrade faster |

| Premium Appearance | Metallic sheen—high perceived value | Customizable, but often lacks metallic finish |

What innovations are emerging in foil materials and design?

Brands are under more and more pressure in the fast changing packaging environment of today to strike a mix between environmental responsibility, customer safety, and product protection. Foil packaging, long known for its strong barrier capabilities, is being redesigned with cutting-edge features that go beyond the essentials. These improvements are about more than just shelf appeal; they are also about future-proofing packaging for the environmentally concerned and technologically savvy age.

As companies shift from traditional multi-layer films to smarter, more sustainable alternatives, the packaging landscape is undergoing a major transformation. From recyclable mono-material pouches to QR-enabled freshness trackers, the focus is no longer just on containment—it’s about performance, sustainability, and consumer interaction.

Through effective market assessment and valuation, businesses are now recognizing that innovative packaging can be a competitive asset, not just a functional layer. The demand for solutions that reduce environmental impact while enhancing brand communication is rising, and understanding the true market potential of these advancements is key to staying ahead.

Listed below are some of the most intriguing and profound breakthroughs currently redefining the foil packaging landscape:

Innovations in Foil Packaging

1. Monomaterial Laminates

New-age recyclable single-material laminates eliminate mixed plastic layers—making recycling easier, aligning with eco-regulations, and supporting closed-loop packaging systems.

2. Smart Seals & QR Integration

Foil packs now feature peel indicators, freshness sensors, and QR codes—offering traceability, real-time tracking, tamper detection, and boosting consumer confidence in product safety.

3. Digital Short‑Run Printing

Custom short-run foil printing allows brands to roll out seasonal, personalized designs quickly—without minimum orders—driving marketing agility and faster brand refresh cycles.

4. Biodegradable/Compostable Coatings

Plant-based coatings and PFAS-free inks replace harmful layers—preserving product shelf life while reducing landfill impact and supporting compostable, low-toxicity end-of-life solutions.

5. Ultra-Lightweight Gauge Reduction

Next-gen foil uses 40% thinner gauges without losing barrier strength—cutting down raw materials, packaging weight, and transportation emissions for more efficient logistics.

6. Heat-Seal Foil Lids & Blister Packs

Innovative tamper-proof blister foils now use PVC-free coatings and ultrasonic seals—offering safer closures for dairy, pharmaceuticals, and ready-to-eat packaging formats.

Foil Packaging in Various Industries

1. Food and beverages

Because of its capacity to preserve flavour and freshness, foil packaging has become the industry standard. It serves the following purposes:

- Instant dinners

- Snacks

- Dairy products

- Coffee and Tea

- Alcohol and soft drink pouches

2. Pharmaceuticals

Pharmaceuticals are more dependent on foil packaging than any other business. The substance ensures:

- Dosage accuracy (blister pack)

- Protection against humidity

- Tamper-evidence

- Safe disposal

3. Cosmetics and Personal Care

Foil sachets and tubes are commonly used for creams, lotions, serums, and perfumes. The packaging maintains product purity while offering a premium experience.

4. Industry and Electronics

Foil wraps and pouches are used to protect delicate electronic components from static, moisture, and environmental conditions.

Benefits of Using Foil Packaging

In a world demanding freshness, safety, and sustainability—foil packaging delivers on all fronts. From preserving flavor to reducing environmental impact, here’s why it’s redefining modern packaging standards:

- Superior Freshness: Creates a powerful barrier against oxygen and moisture, locking in taste, aroma, and product integrity.

- Extended Shelf Life: Delays spoilage of perishable goods—essential for food, pharma, and personal care items.

- Lightweight Efficiency: Cuts shipping weight, lowers freight emissions, and supports cost-effective global distribution.

- Tamper-Evident Seals: Adds visible safety features that boost consumer trust, especially for food and medical applications.

- High-Impact Design: Metallic shine and smooth surface enable eye-catching finishes and premium branding.

- Enhanced Printability: Supports crisp graphics, vibrant colors, and specialty finishes for greater shelf visibility.

- Versatile Applications: Adapts effortlessly to snacks, ready meals, cosmetics, pharmaceuticals, and industrial goods.

- Puncture Resistance: Offers durability and tear resistance that outperform paper or basic plastic wraps.

- Eco-Friendly Potential: Monomaterial and recyclable variants support circular economy initiatives with lower lifecycle impact.

Market Outlook for Foil Packaging Materials

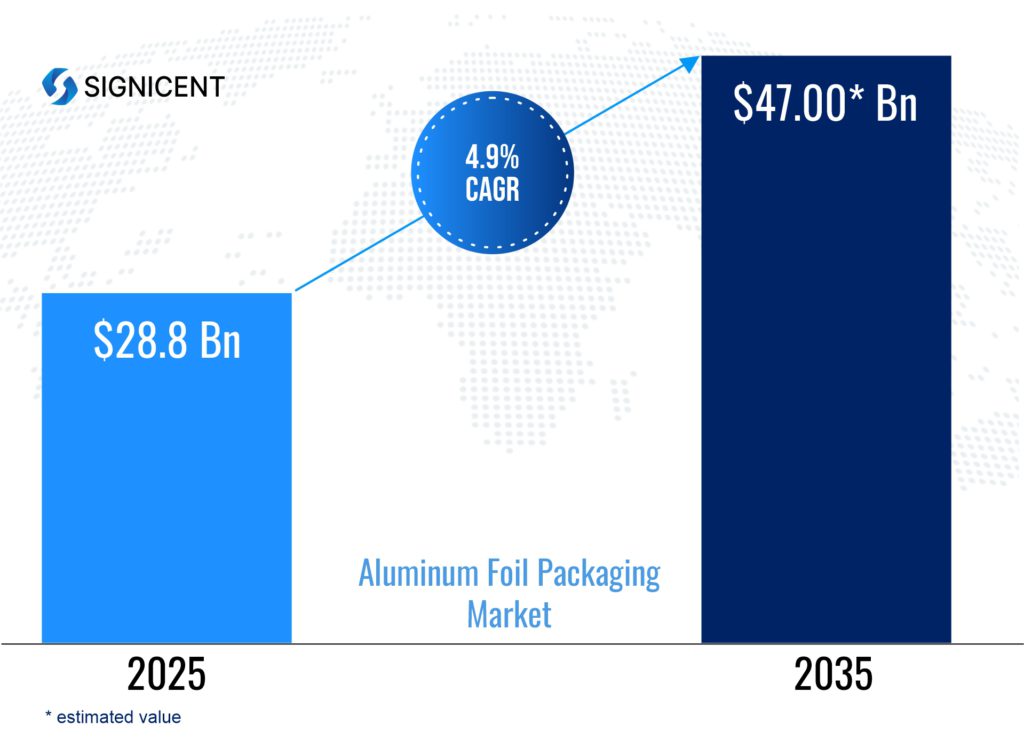

The foil packaging market is steadily expanding, fueled by the rising need for high-performance, lightweight, and sustainable barrier materials across food, pharmaceuticals, and personal care industries. As shelf-life, safety, and sustainability become top priorities, foil emerges as a trusted solution balancing function and eco-efficiency.

According to Signicent Market Research, the global foil packaging sector is set to witness robust growth—driven by innovations in monomaterial laminates, biodegradable coatings, and advanced sealing technologies. Additionally, the push for PVC-free, recyclable foils and PFAS-free coatings is aligning with global compliance trends and circular packaging initiatives.

Key Players in Foil Packaging

- Amcor plc

- Constantia Flexibles

- Novelis

- Hindalco Industries

- UFlex

- Alcoa Corporation

- Reynolds Group Holdings

Signicent supports package innovators by providing detailed technology landscape assessments on high-barrier materials, monomaterial foil laminates, biodegradable coatings, and lightweight aluminium composites. Our patent landscape analysis identifies whitespace in smart seal technologies, PFAS-free barriers, and QR-enabled traceability, allowing businesses to future-proof their R&D and match with next-generation sustainability goals. We actively evaluate emerging firms, compare alternative foil materials, and look for co-development or licensing opportunities to accelerate eco-friendly packaging processes.

We also provide thorough regulatory information and Freedom to Operate (FTO) assessments based on worldwide packaging regulations such as EU Packaging and Packaging Waste Regulations, EPR guidelines, and FDA/EFSA standards. Through competitive benchmarking and sustainability mapping, Signicent helps clients lower material intensity, enhance recyclability, and transition toward circular packaging systems. With our insights, companies can reduce environmental impact, increase compliance, and stay ahead in the rapidly evolving sustainable packaging market.

Conclusion

Foil packaging has developed into a vital tool for brands looking for performance, sustainability, and safety; it is no longer just a flashy wrap. Nowadays, foil is a crucial component of contemporary packaging techniques, whether it is used to preserve freshness, guard against outside hazards, or offer traceability via smart seals and QR codes. Innovations such as monomaterial laminates, biodegradable coatings free of PFAS, and ultra-lightweight designs are assisting businesses in shifting from obsolete, wasteful materials to more circular, environmentally friendly models.

However, it takes more than simply brilliant ideas to stay ahead of this shift; it also takes strategic vision and keen observations. That’s where Signicent steps in—bridging gaps between ideas and implementation with technology scouting, patent mapping, and regulatory foresight. As the packaging landscape shifts, embracing smarter foil solutions isn’t just a trend—it’s a strategic move toward a circular, sustainable future.

FAQs

Q1. Is foil packaging eco‑friendly?

A1. Pure aluminum foil is 100% recyclable and can be reused indefinitely. Monomaterial laminates and compostable coatings help improve sustainability.

Q2. Can foil packaging be microwaved?

A2. No. Microwaving foil can cause sparking. Only remove foil before heating; then re‑seal if resealable pouch.

Q3. Is foil packaging more expensive than alternatives?

A3. It can cost more than basic plastic or paper. But high barrier protection and premium branding often justify the higher price.

Q4. How do you recycle foil packaging?

A4. Clean foil must be separated from plastic liners. If laminated, follow local recycling guidance or return via take‑back schemes.

Q5. Can foil packaging be customized?

A5. Yes. Digital printing enables short‑run customization, variable data like names, and color‑rich brand designs.

Q6. What are emerging trends in foil packaging?

A6. Smart packaging with QR codes/RFID, biodegradable coatings, minimalist resealable designs, and ultra‑light foils are gaining traction.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Patent Landscape

- Patent Portfolio Analysis

- Patent Invalidity Search

- Patent Licensing Services

- Freedom to operate (FTO)

- Chemical Structure Search

- Design Patent Search

- Technology Scouting

- Technology Landscape Analysis

- Technology gap analysis

- Technology Intelligence

- Market Research

- Bio Sequence Search

Elevate your Innovation and Research with Signicent’s cutting-edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.