In today’s fast-paced technological landscape, the lifespan of electronic devices is increasingly challenged by heat generation. High-power electronics, which are integral to various applications, tend to heat up rapidly, risking battery swelling and the release of toxic gases. This situation not only compromises device performance but can also lead to catastrophic failures. Therefore, effective thermal management has become essential to maintain reliability and enhance the performance of these devices.

Signicent performs comprehensive Patent Chemical Structure Searches for thermal management in high-power electronic devices, identifying relevant innovations and enhancing technology development through strategic insights.

Understanding Heat Generation in High-Power Electronics

Electronic devices generate heat through high current flow and the switching of components like transistors. This heat buildup, if unmanaged, can cause problems such as:

- Semiconductor Instability: The internal components become unstable when operating at high temperatures.

- Material Fatigue: Over time, materials degrade under constant thermal stress.

- Electromigration: High temperatures cause atoms in metal conductors to move, leading to electrical failures.

What is the reason for heat generation in devices?

High current flow through electronic components generates heat, which can destabilize semiconductor behavior, induce material fatigue, and lead to electromigration. Each of these effects can cause performance degradation, impacting the overall functionality of the device.

Challenges in Current Thermal Management Systems

As devices become more powerful and compact, managing heat efficiently becomes increasingly difficult. The main challenges in today’s thermal management systems include:

- Low Thermal Conductivity of Materials: Traditional materials used in electronics like plastics and standard thermal pastes have poor thermal conductivity. This limits how effectively heat is transferred from components to the cooling system.

- High Power Density: With devices like electric vehicles and high-performance computers, the amount of power flowing through a small area generates concentrated heat. This leads to hot spots, which can degrade performance or cause failures.

- Thermal Stresses: Different materials used in devices have varying coefficients of thermal expansion (CTE). This mismatch can lead to thermal stress that weakens the bond between materials, increasing the risk of cracks and mechanical failure.

How do thermal stress and power density affect the longevity of high-power devices?

Thermal stress and high-power density increase heat, which accelerates component wear. Without effective heat management, this significantly reduces the lifespan and reliability of high-power devices. Proper cooling ensures longer device performance.

Signicent conducts thorough Patent Invalidation Searches in thermal management, assessing existing patents to identify vulnerabilities and support clients in strengthening their competitive edge.

Innovative Solutions for Effective Thermal Management

To address the challenges outlined above, several innovative solutions can be implemented:

- Heat Sinks and Heat Spreaders: These components increase the surface area for heat dissipation, significantly reducing thermal resistance.

- Thermal Interface Materials (TIMs): TIMs improve thermal conduction between components and heat sinks, enhancing heat transfer efficiency.

- Liquid Cooling Systems: Utilizing liquid cooling, such as cold plates or microchannel heat exchangers, can effectively remove heat from high-power components, surpassing traditional air cooling methods.

- Active Cooling Techniques: Fans and blowers enhance air circulation around components, improving heat dissipation.

- Thermal Vias and Conduction Pathways: Incorporating conductive pathways within PCBs helps extract heat effectively, promoting even heat distribution.

- Component Placement: Strategic placement of high-power components can minimize thermal coupling and prevent hot spots.

- Thermal Simulations: Using computational fluid dynamics (CFD) and finite element analysis (FEA) allows for the optimization of thermal designs by predicting and mitigating thermal issues early in the development process.

Signicent excels in Technology Scouting for thermal management, identifying emerging innovations and trends to help clients enhance performance and efficiency in high-power electronic devices.

Benefits of using these materials:

- Graphene and Carbon-Based Materials: Graphene offers superior thermal conductivity over traditional materials like silicon, while carbon nanotubes enhance heat dissipation as thermal interface materials (TIMs).

- Metal Matrix Composites (MMCs): Aluminum and copper-based composites combine metals with ceramics or polymers, providing strong heat sinks and spreaders with excellent thermal conductivity.

- Phase Change Materials (PCMs): PCMs absorb excess heat during phase transitions and release it when temperatures drop, stabilizing device temperature effectively.

- Advanced Thermal Interface Materials (TIMs): Liquid metals and carbon-based pastes bridge gaps between components and heat sinks, improving thermal conductivity.

- Ceramic-Based Heat Spreaders: Lightweight ceramics like Aluminum Nitride (AlN) and Silicon Carbide (SiC) offer high thermal conductivity, ideal for electronics where metals may degrade.

- Diamond-Like Carbon (DLC) Coatings: DLC coatings reduce friction and enhance heat dissipation, increasing the lifespan of high-power electronics.

Signicent conducts Technology Gap Analysis for thermal management, pinpointing deficiencies in current solutions and recommending advancements to optimize high-power electronics performance and reliability.

Market Dynamics and Leading Players:

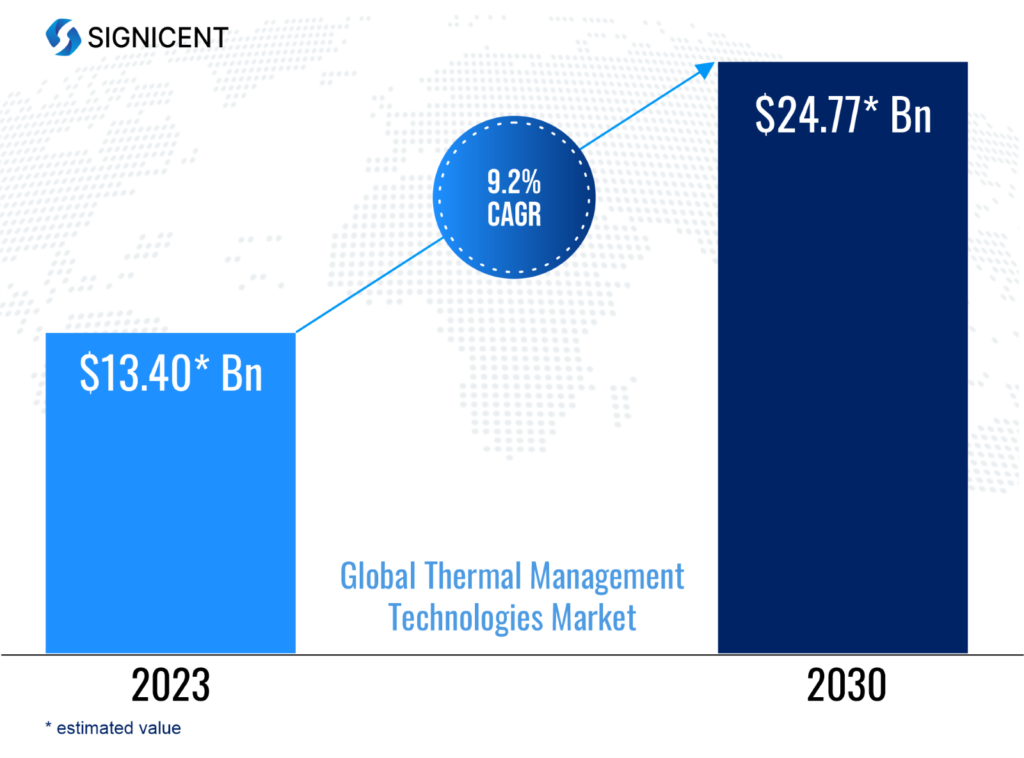

As per signicent’s market research, the global market for thermal Management technologies is projected to grow at a compound annual growth rate (CAGR) of over 9.2% by 2030.

Signicent’s Contribution to Thermal Management Innovation

At Signicent, we are committed to helping our clients navigate the challenges of thermal management in high-power electronics by offering comprehensive solutions tailored to their specific needs. We provide:

- Patent Landscape Analysis: Understanding the latest innovations and technologies available for effective thermal management.

- Technology Scouting: Identifying advanced materials like graphene, MMCs, and ceramics that can improve heat dissipation in your products.

- Thermal Management Consulting: Helping businesses implement the latest cooling techniques, such as liquid cooling systems, advanced TIMs, and thermal vias.

By working with Signicent, you gain access to the latest innovations in materials and strategies, ensuring your devices remain competitive, reliable, and efficient in today’s high-power electronics landscape.

Signicent’s Freedom to Operate (FTO) Search Services for thermal management assess existing patents, ensuring clients navigate intellectual property landscapes effectively for high-power electronics innovations.

Conclusion

Efficient thermal management is vital in ensuring the optimal performance and longevity of high-power electronics. As technology continues to advance, the need for innovative thermal solutions will only increase. By embracing advanced materials and strategies, manufacturers can effectively manage heat and enhance the reliability of their products.

As you navigate the complexities of thermal management in your projects, consider partnering with experts like Signicent. Our understanding of thermal management principles can lead to tailored solutions that meet your specific needs.

FAQs

Why is thermal management important for high-power electronics?

Thermal management ensures that devices operate within safe temperature ranges, preventing performance degradation and extending component life.

What are the most commonly used materials in advanced thermal management systems?

Materials like graphene, metal matrix composites (MMCs), ceramics, and phase change materials (PCMs) are used to improve heat dissipation and reduce thermal stress.

How do TIMs improve the thermal management of devices?

Thermal Interface Materials (TIMs), such as liquid metals and carbon-based pastes, enhance heat conduction between components and heat sinks by minimizing microscopic gaps that trap heat.

What is Signicent’s role in solving thermal management challenges?

Signicent provides services like patent landscape analysis and technology scouting to help businesses identify and implement cutting-edge materials and solutions for effective thermal management.

How do phase change materials (PCMs) work in managing heat?

PCMs absorb excess heat during phase transitions, such as when changing from solid to liquid, and release that heat as the temperature drops, helping to stabilize device temperatures.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Patent Landscape

- Patent Portfolio Analysis

- Patent Invalidity Search

- Patent Licensing Services

- Freedom to operate (FTO)

- Chemical Structure Search

- Design Patent Search

- Technology Scouting

- Technology Landscape Analysis

- Technology gap analysis

- Technology Intelligence

- Market Research

- Bio Sequence Search

- Manufacturers Search/ Supplier search

Elevate your Innovation and Research with Signicent’s cutting edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.