The oil and gas industry has been a significant source of global energy for over a century, supporting industries, transportation, and households. However, with rising energy demands, aging infrastructure, and stricter environmental regulations, the sector faces increasing challenges. Traditional extraction methods, though effective in the past, are no longer sufficient to meet current energy needs or ensure sustainable profitability.

In the present market, both efficiency and sustainability are essential. To remain competitive, oil and gas companies must shift from conventional practices and adopt more advanced methods to improve production efficiency, reduce environmental impact, and maintain profitability in a changing market.

Signicent optimizes oil and gas production by providing Technology Landscape Analysis, which identifies innovations, increases efficiency, and reduces costs through strategic insights.

Challenges faced by the Oil & Gas Sector

Despite advancements, the oil and gas industry continue to face significant challenges that hinder its ability to operate at optimal efficiency. Here are some of the major challenges:

Aging Infrastructure: Many oil rigs and refineries have been operating for decades, and the infrastructure often struggles to keep up with modern production demands. The lack of real-time monitoring systems leads to inefficiencies, equipment failures, and costly downtime.

Environmental Impact: The industry is heavily scrutinized for its environmental footprint. Carbon emissions, oil spills, and groundwater contamination are persistent issues that require innovative solutions to meet increasingly stringent environmental regulations.

Operational Inefficiencies: Managing operational costs while improving production efficiency remains a challenge. Fluctuating oil prices, outdated technology, and high operational expenses limit the profitability of oil and gas companies.

Declining Well Production: Aging oil fields lead to reduced output and increased costs, challenging profitability as extraction becomes more expensive and maintenance efforts intensify.

Market Volatility: Geopolitical instability and fluctuating oil prices create uncertainty, complicating demand and supply forecasts, and making financial planning and strategic investments difficult.

What strategies help the oil and gas sector improve efficiency and sustainability?

Key strategies include deploying IoT sensors for predictive maintenance, using AI to optimize production workflows, and implementing carbon capture technologies. These approaches reduce operational costs, minimize downtime, and decrease environmental harm.

Signicent conducts Patent Invalidation Searches, identifying weak claims in competitor patents to help protect your innovations and ensure market freedom.

Innovative Technologies Shaping the Future of Oil & Gas Production

To tackle the aforementioned challenges, following are the possible innovative solutions:

Aging Infrastructure:

Intelligent Well Completions: These systems help modernize aging infrastructure by providing real-time data for remote monitoring and control of well operations. This technology reduces the need for on-site physical intervention, minimizing downtime and equipment failures.

For instance, CNX Resources used intelligent completions to optimize well productivity, which not only boosted output but also reduced greenhouse gas emissions.

Digital Twins: Digital twins create virtual replicas of aging rigs and refineries, allowing operators to simulate and optimize maintenance processes. This proactive maintenance helps prevent equipment failures before they occur, reducing costly downtime.

Companies like British Petroleum have leveraged digital twins for more efficient operations and better decision-making.

Environmental Impact:

- Enhanced Oil Recovery (EOR): EOR techniques, such as CO2 injection and thermal recovery, enable companies to extract more oil from existing wells, reducing the need for new drilling. By increasing yield without further environmental damage, these technologies help minimize the carbon footprint of extraction processes.

Chevron, for instance, uses EOR to extend the life of mature fields while mitigating environmental harm. - Artificial Lift Optimization: Optimizing systems like electric submersible pumps (ESPs) reduces emissions by making energy use more efficient.

Bowline Energy’s use of AI-driven artificial lift optimization reduced operational costs while improving production efficiency and lowering environmental impact. - Automation and Robotics: Autonomous vehicles and robotic systems streamline remote operations, reducing human exposure to hazardous environments and increasing precision. British Petroleum employs autonomous underwater vehicles (AUVs) for offshore pipeline inspection, enhancing operational safety and efficiency.

- Advanced Materials: Lightweight, corrosion-resistant materials improve equipment durability and reduce energy consumption. ExxonMobil’s investment in advanced materials has significantly enhanced the performance of equipment in harsh oil and gas environments, cutting down on maintenance and operational costs.

- Energy Management: Energy-efficient technologies and renewable energy integration, such as solar and wind power, reduce reliance on fossil fuels. Chevron has implemented solar power projects at multiple facilities, which have helped lower carbon emissions and energy expenses, promoting long-term sustainability.

- Enhanced Oil Recovery (EOR): EOR techniques, such as CO2 injection and thermal recovery, enable companies to extract more oil from existing wells, reducing the need for new drilling. By increasing yield without further environmental damage, these technologies help minimize the carbon footprint of extraction processes.

Chevron, for instance, uses EOR to extend the life of mature fields while mitigating environmental harm. - Artificial Lift Optimization: Optimizing systems like electric submersible pumps (ESPs) reduces emissions by making energy use more efficient.

Bowline Energy’s use of AI-driven artificial lift optimization reduced operational costs while improving production efficiency and lowering environmental impact.

AI and ML revolutionize production by predicting failures and optimizing reservoir management. IoT devices provide real-time monitoring, cloud computing boosts data insights and global collaboration, and advanced hydraulic fracturing unlocks hidden reserves, driving unprecedented efficiency.

Signicent offers Biological Sequence Search services, helping identify relevant sequences in patent databases, ensuring your innovations are unique and protected.

Why should oil and gas companies invest in these technologies?

- Increased Efficiency: Advanced technologies enable precise monitoring, predictive maintenance, and optimized resource use, ensuring that every drop of oil is extracted as efficiently as possible.

- Cost Reduction: Automation and AI reduce the need for human labor and lower operational costs by preventing breakdowns and optimizing drilling schedules.

- Improved Safety: Robotics and automation limit human involvement in dangerous environments, reducing the risk of accidents.

- Environmental Sustainability: EOR and IoT technologies contribute to reducing environmental impact by optimizing resource use and decreasing emissions.

Signicent provides Technology Scouting Services to identify emerging technologies and innovations, ensuring your business stays ahead of industry trends and competition.

Market Forecast and Future Trends

How will the oil and gas industry evolve in the future?

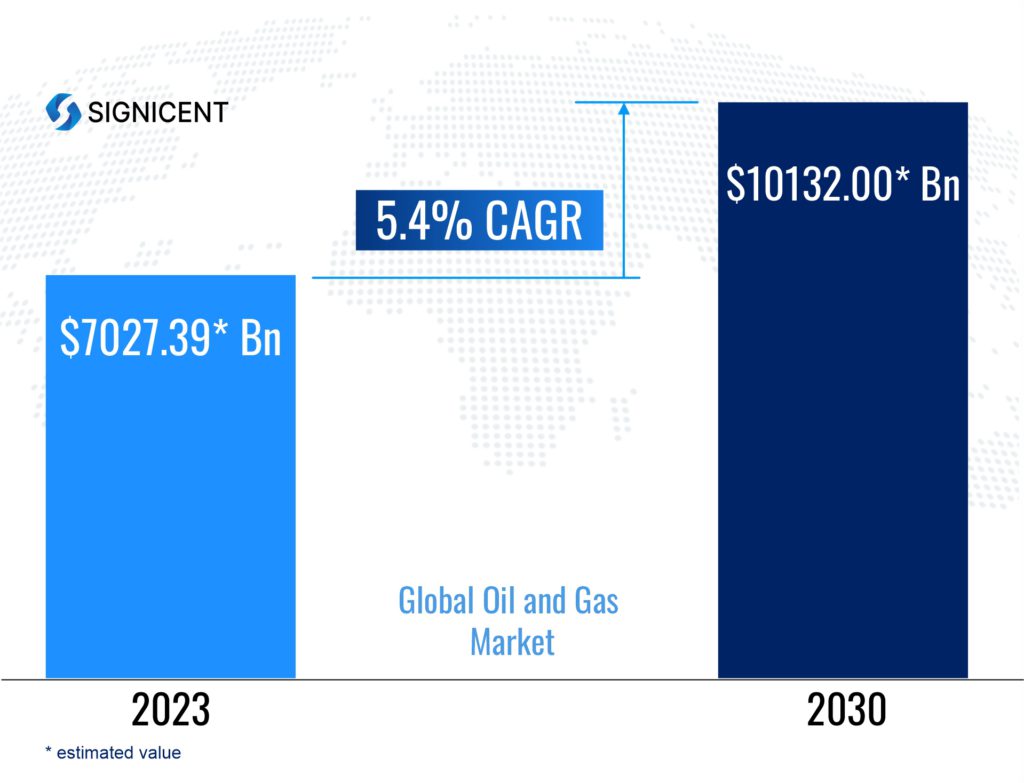

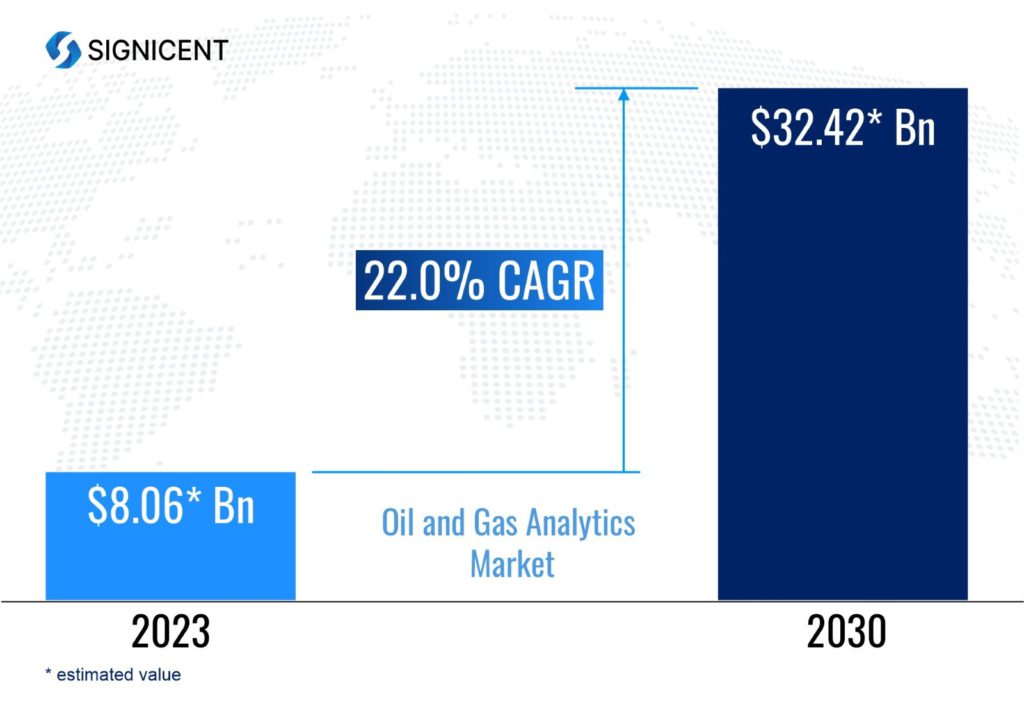

The oil and gas optimization market is expected to grow significantly due to increasing demand for energy and environmental sustainability. According to Signicent’s Market Researchers, the global market for oil and gas optimization technologies likely to reach values in the ranges shown below.

Signicent offers Market Assessment and Valuation services, helping businesses evaluate market potential, identify opportunities, and make informed investment decisions.

Global Oil & Gas Analytics market

This growth is driven by advancements in AI, IoT, and EOR, with a strong focus on reducing emissions and improving operational efficiency.

As companies continue to invest in these technologies, the analytics market is poised for continued expansion, driven by the need for smarter, more sustainable operations.

Key Players in Oil & Gas Optimization

Several companies are leading the charge in oil and gas production optimization:

Signicent plays a crucial role in supporting oil and gas companies with advanced technological solutions and intellectual property services. Through Technology Scouting Services and Technology Landscape Analysis, Signicent helps companies identify emerging trends and integrate the latest innovations into their operations. Additionally, Competitive Intelligence and Patent Landscape Services allow companies to understand the competitive landscape, positioning them to lead the market.

Conclusion: A Future Built on Innovation

The oil and gas industry’s future depends on its ability to adapt to changing market conditions, environmental regulations, and technological advancements. By optimizing production processes and embracing new technologies such as AI, IoT, and EOR, companies can not only boost profitability but also ensure long-term sustainability. Signicent stands at the forefront of this transformation, providing invaluable research, technology scouting, and patent analysis to support oil and gas companies in their optimization journey. As the industry continues to evolve, those who prioritize innovation will lead the way in a competitive and increasingly regulated market.

Frequently Asked Questions (FAQ)

Q1: What are the key technologies for optimizing oil and gas production?

A: AI, IoT, enhanced oil recovery (EOR), robotics, and big data analytics drive production efficiency and operational improvements.

Q2: How does AI benefit oil and gas production?

A: AI predicts equipment failures, optimizes reservoir management, and provides data-driven insights for better decision-making and efficiency.

Q3: What role does IoT play in oil and gas operations?

A: IoT enables real-time monitoring, predictive maintenance, and enhanced operational efficiency by continuously tracking equipment and flow rates.

Q4: How can Enhanced Oil Recovery (EOR) techniques improve production?

A: EOR techniques boost oil extraction from aging fields, extending reservoir life and increasing recovery rates without new drilling.

Q5: How does Signicent assist in the oil and gas sector?

A: Signicent provides technology scouting, market intelligence, and patent analysis to help clients optimize production and plan strategically.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Patent Landscape

- Patent Portfolio Analysis

- Patent Invalidity Search

- Patent Licensing Services

- Freedom to operate (FTO)

- Chemical Structure Search

- Design Patent Search

- Technology Scouting

- Technology Landscape Analysis

- Technology gap analysis

- Technology Intelligence

- Market Research

- Bio Sequence Search

- Manufacturers Search/ Supplier search

Elevate your Innovation and Research with Signicent’s cutting edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.