As the world becomes increasingly digital and automated, the automotive industry is undergoing a significant transformation. The shift towards electric and autonomous vehicles is setting new standards, not only in terms of technology but also in the pursuit of reducing carbon footprints. This global trend is particularly evident in key automotive markets such as the United States, China, and Japan, where innovation is driving the demand for more sustainable and fire-resistant materials. Among these, self-adhesive tapes and wires used in automotive applications, particularly in electric vehicles and their battery systems, are at the forefront of this evolution. The need for these materials to withstand extreme temperatures is critical to ensure the safety and reliability of the next generation of vehicles.

This blog delves into the latest sustainable fire-resistant materials, highlighting the challenges, innovations, and key market drivers. Signicent provides Technology intelligence to uncover emerging technologies, assess risks, and identify solutions for a strong business strategy.

Why High-Temperature Materials Matter?

When it comes to EVs and autonomous vehicles, the stakes are high. The batteries powering these vehicles generate significant heat, especially under heavy load or during rapid charging. Traditional materials, which can only handle temperatures up to 750°C, are no longer sufficient. This gap in thermal protection poses serious risks, including the potential for vehicle fires or critical system failures, often occurring in the middle of the road or on busy runways.

Real-Life Challenges

One of the significant challenges in the automotive industry today is the need for materials that can withstand temperatures exceeding 1000°C. Currently, many tapes and wires on the market can only tolerate temperatures up to 750°C. This limitation poses a serious risk of vehicle and battery damage, particularly in high-stress environments such as on roadways and runways.

When these materials fail, the consequences can be catastrophic, leading to vehicle fires and potential loss of life. The challenge is further exacerbated by the rapid advancements in automotive technology, particularly in electric vehicles, which demand even higher safety standards.

Ensuring fire-resistant tapes maintain performance and adhesion in high temperatures, while overcoming cost barriers and integrating new materials into existing technologies, is complex and costly.

Environmental Balance: Many fire-resistant materials still use non-recyclable or harmful components, complicating the balance between safety and sustainability.

Signicent leads in Technology convergence, merging innovations to reveal synergies, reduce risks, and craft strategies that drive future success.

Why Use Sustainable Fire-Resistant Materials?

The growing emphasis on sustainability and safety in the automotive sector has led to an increased demand for materials that are not only fire-resistant but also environmentally friendly. Self-adhesive tapes and wires play a crucial role in the construction of electric vehicles, particularly in securing battery components and wiring harnesses. These materials must be able to withstand high temperatures, prevent the spread of flames, and maintain their integrity under extreme conditions.

The benefits of using sustainable fire-resistant materials in the automotive industry are multifaceted:

- Enhanced Safety: These materials help prevent vehicle fires, particularly in electric vehicles where battery safety is paramount.

- Environmental Impact: Sustainable materials reduce the overall carbon footprint of vehicles, contributing to global efforts to combat climate change.

- Durability: High-temperature resistant materials ensure the longevity of automotive components, reducing the need for frequent replacements and repairs.

- Compliance: Using these materials helps manufacturers meet stringent safety and environmental regulations in key markets.

Innovation at Its Best: Advanced Materials for Extreme Conditions

In response to these challenges, companies like from Switzerland are leading the way in developing high-temperature resistant materials. Von Roll has demonstrated system prototypes in operational environments that can withstand temperatures ranging from 950°C to 1400°C. These advancements are critical in ensuring the safety and reliability of automotive components, particularly in electric vehicles.

Some of the materials and coatings being tested for their flame-retardant properties include:

- PVC (Polyvinyl Chloride): Known for its excellent fire-resistant properties and chemical resistance, PVC is widely used in automotive wiring and insulation.

- Polyethylene: This material offers high thermal conductivity and tensile strength, making it ideal for use in high-temperature environments.

- Nickel-Copper-Iron Laminates: These laminates provide superior thermal resistance and are increasingly being used in applications that require durability under extreme conditions.

- Silicone Coatings: Silicone-based materials offer excellent fire resistance and flexibility, making them suitable for a wide range of automotive applications.

Nanotechnology Integration: Using nanomaterials in fire-resistant tapes boosts performance and durability, providing enhanced fire resistance while using less material.

Bio-Based Materials: Researchers are developing fire-resistant tapes from renewable bio-based polymers, enhancing sustainability without compromising fire safety.

Smart Tape Solutions: Smart tapes with integrated sensors offer real-time monitoring of temperature and safety, representing a significant advancement in self-adhesive technology.

Properties of Sustainable Fire-Resistant Materials

The key properties that make these materials suitable for automotive applications include:

- Fire Resistance: Ability to withstand high temperatures without igniting or spreading flames.

- High-Temperature Resistance: Materials that can endure temperatures above 1000°C, ensuring the safety of automotive components.

- Thermal Conductivity: Efficient heat dissipation to prevent overheating and damage to sensitive components.

- Peel Strength: The ability of adhesives to maintain a strong bond under high temperatures.

- Tensile Strength: Durability and resistance to tearing or breaking under stress.

- Chemical Resistance: Protection against corrosion and degradation from exposure to chemicals.

- Shelf Life: Long-lasting materials that remain effective over time, reducing the need for replacements.

Market Research and Industry Trends

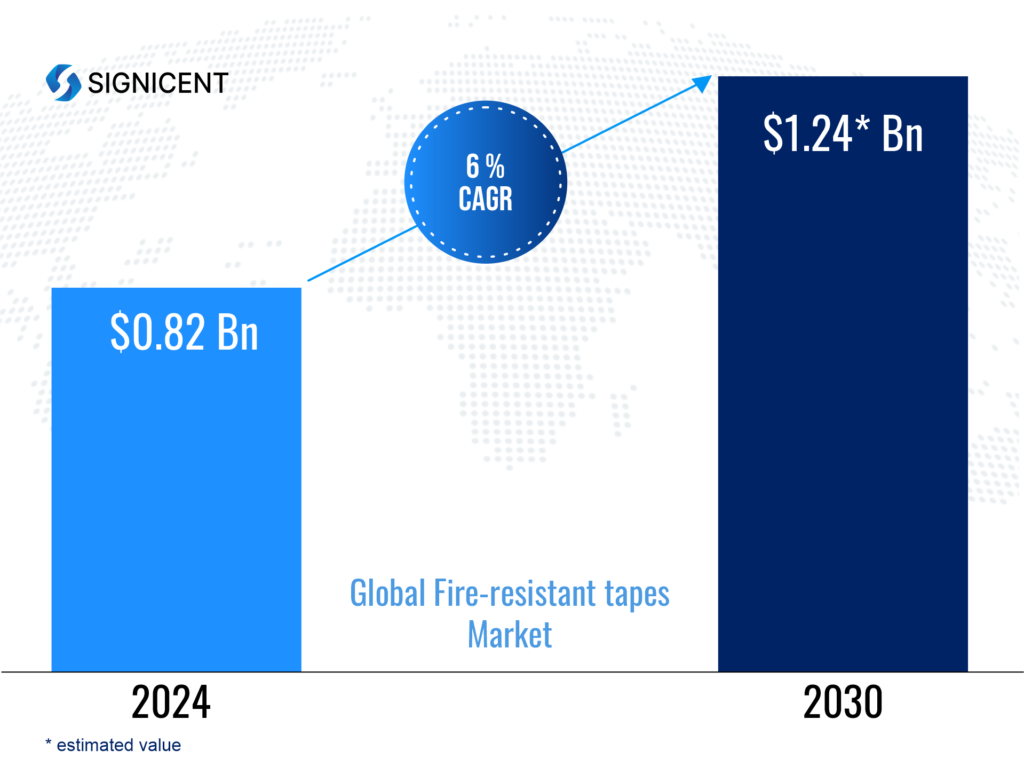

The global market for sustainable fire-resistant materials is poised for significant growth, driven by the increasing demand for electric vehicles and the stringent safety regulations in key markets. The market is expected to expand as more automotive manufacturers adopt these materials to ensure the safety and reliability of their vehicles.

As per Signicent’s Market Researchers, the Global Fire-Resistant Lubricants Market size is likely to reach values in the ranges shown below.

Emerging Key Players in the Market

The market for sustainable fire-resistant materials is growing rapidly, with several key players driving innovation and market expansion:

- Von Roll Inc.: A leader in high-temperature resistant materials, Von Roll is pioneering solutions for the automotive industry.

- Avery Dennison: Known for their advanced adhesive technologies, Avery Dennison is at the forefront of developing fire-resistant tapes and coatings.

- Lintec Corporation: Specializing in adhesive products, Lintec is expanding its offerings to include sustainable, high-temperature resistant materials.

- SWM International: A global leader in engineered materials, SWM is focusing on developing durable and fire-resistant solutions for automotive applications.

- Poly Ram Group: With a strong focus on innovation, Poly Ram is contributing to the development of next-gen materials for electric and autonomous vehicles.

Signicent is at the forefront of this industry transformation, providing cutting-edge technical scouting and technology readiness level to help companies identify and adopt the best materials for their needs. Our in-depth market research and insights into emerging trends allow us to guide our clients toward innovative, sustainable solutions that meet the highest safety standards.

Our team has been instrumental in helping clients navigate the complexities of developing and implementing fire-resistant materials in their products. With a focus on innovation and sustainability, Signicent is committed to supporting the automotive industry as it moves towards a safer and greener future.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Technology Intelligence

- Market Research

- Patent Landscape

- Technology gap analysis

- Design Patent Search

- Portfolio Analysis

- Freedom to operate

- Bio Sequence Search

- Innovation pipeline identification

- Chemical Structure Search

- Patent Invalidity Search

- Manufacturers Search/ Supplier search

- Patent Licensing Services

Elevate your Innovation and Research with Signicent’s cutting edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.