This report will shed light on Optimization of Energy Density in Electric Vehicle (EV) battery, get free primer here.

It is estimated that EVs will make two thirds of all road vehicles by 2050.

There is a lot of competition in the market. The launch of models like Tesla, BMW i3s, Rimac C_Two, Porsche Mission E, Nissan’s second-generation Leaf EV, Aston Martin RapidE and Nio ES8 has set high competition.

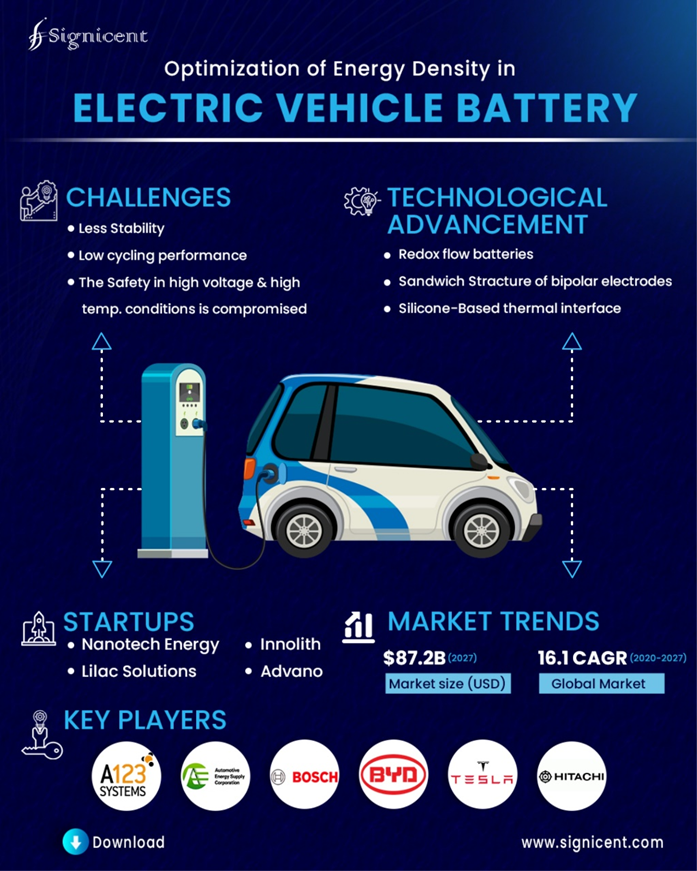

The electric vehicle battery market size has been projected to reach $87.2 billion by 2027, registering a CAGR of 16.1% from 2020 to 2027.

Traditional vehicles emit immense CO2 and contribute a lot to air pollution. These emissions act as catalysts for global warning. Lately, most of the firms are trying for Electronic Vehicles as a way to affirm that they are socially responsible. Few years back the availability of electric car charging stations were not readily available. Today, a lot of innovations are happening to overcome the problems associated with EV and batteries. Governments across the globe are providing financial help to the firms who are extensively working in EV to promote sustainability.

Evolution of Cell Technology in Battery Packs

Over the period of time, batteries have undergone evolution. The cell technology in battery packs has evolved. The Optimization in energy density of cell is done to increase the travel time/ range. The solid-state batteries have established themselves in the market for being a higher energy density as compared to Li-on battery.

The Challenges faced in battery packs are low cycling performance and less stability. Further, the safety in high voltage and high temperature conditions is compromised.

Technological Advancement to Improve Energy Density in Electric Vehicle Battery

Energy Density is the measure of the amount of energy that a battery contains in proportion to its weight. This measurement is specifically represented in Watt-hours per kilogram (Wh/kg). A watt-hour is a measure of electrical energy that is equivalent to the consumption of one watt for one hour.

The challenges such as low cycling performance, less stability, safety in a high voltage and high temperature conditions were analyzed. To overcome the challenges associated with battery packs a lot of advancement has been made. We have discussed some of them below.

To get other similar solutions or conduct desired research and analysis in Electric Vehicles/ Battery area, you may contact Signicent.

Here is the list of some of the emerging technologies in increasing energy density:

- Redox flow batteries

- Sandwich structure of bipolar electrodes

- Silicone-Based Thermal Interface

US10573882B2 Guizhou Zhenhua E-Chem (China) discloses the efficiency of battery was increased tremendously when the material of cathode was layered with lithium-nickel-cobalt-manganese composite oxide. In this study, the material had a spherical or spherical-like layered structure. The cathode material had a morphology of spherical or spherical-like primary mono-crystal particles.

Fraunhofer Munich, Germany: The collaboration with Lithium-ion for the industrialization of bipolar batteries produced an amazing product. EMBATT is the product that has a sandwich structure. It comprises of bipolar electrodes that span approximately two square meters. The capacity of the battery with respect to energy density inclined drastically which is commendable.

Future Belongs to High Energy Density in Electric Vehicle Battery

The most significant reason is that a battery with high energy density has a longer battery run time with respect to the battery size. Alternately, a battery with high energy density can deliver the same amount of energy, but in a smaller footprint compared to a battery with lower energy density. This greatly expands the possibilities for battery applications.

After increasing the energy density, same size of battery can deliver more energy as compared to battery with less energy density. Optimization of Battery to increase the travel time/ range is another approach. The following technologies are emerging in this field:

- Hybrid, pseudo and electrochemical supercapacitors

- NanoBolt lithium tungsten batteries

- Quasi-solid lithium-ion battery

Case Study on low energy density and difficulty in processability

Technological Advancement in Quasi-solid lithium-ion battery has emerged as a fascinating technology (CN111864272A Jiangsu University, China)

The isotropic polyphenylene sulfide solid electrolyte is manufactured by undergoing three steps. The three methods are by adopting a solvent-independent method, manufacturing a high-load battery pole piece and assembling the quasi-solid-state lithium-ion battery.

It is observed that the volume ratio of the active substance load is increased to 30%-50%.

The polyphenylene sulfide solid electrolyte offers good flame retardant property. It was observed that it also has good thermal stability; therefore, the electrolyte injection amount is reduced. Moreover, it helps in reducing the electrolyte dosage as well as combustibles in the battery. And the safety performance of the battery is improved.

Consumption of large amount of the electric power stored in the vehicle’s main battery (EP3103158B1, Phinergy Ltd, Italy)

This reference discloses the usage of a supplementary battery (metal-air battery) to run secondary functions other than driving motors. For, instance, using cabin heating/cooling, music system etc. Whereas the main battery is used for driving the vehicle by not compromising the travel time/ range.

It provides us with a system for heating one or more components in an electric vehicle. The system comprises of a supplementary battery that has a metal-air battery. This battery has an electrolyte; a reservoir tank for holding the electrolyte for the metal-air battery and a heating element.

QuantumScape California, US: It has produced a Solid-state lithium metal battery. This battery is known to charge 80 percent capacity in just 15 minutes, which is commendable. Another astonishing feature is that it nearly doubles the energy density of top commercial lithium-ion cells. It has the capability to retain more than 80 percent of their capacity after 800 cycles.

We are consistently tracking the changes in the innovations in Electric Vehicle Battery area. Our experience and understanding of the area can help better R&D, help solve the bottleneck, find suppliers and understand the state of art search. Contact Signicent, for further information.

Startups to Collaborate in Electric Vehicle Battery

Nanotech Energy: It is Headquartered in Chico, California (US). It deals with Graphene, graphene oxide and graphene super batteries. These are Non-flammable, environment friendly lithium battery and has 18 times faster charging time.

Lilac Solutions: It is based in Oakland, California (US). It is working to extract lithium with unique ion exchange technology. It helps in lowering the cost of lithium production while increasing the speed.

Innolith : It is headquartered in Basel (Switzerland) . They work in rechargeable Inorganic Battery and High-density batteries. 1,000 kilometers (621 miles) of travel range on a single charge.

Advano: It is based in New Orleans, Louisiana. They work on Scalable silicon solution for li-ion batteries. The Silicon nanoparticles increase the energy density by 30-40%.

The difference in vision can make all the changes. It is always good to stay ahead by investing on future technology. The future ofthe battery technology in EV industry willfocuson customer convenience, compliance. It has a very promising future. Contact Signicent to know more.

Key Competitors in the Area

- A123 Systems

- Automotive Energy Supply (AESC)

- Bosch

- BYD

- E-One Moli Energy

- Hitachi

- Tesla

Recent Report

- How EU Regulations Shape Product Safety, Sustainability and Business Compliance

- Transparent Solar Panels Powering Smart and Green Cities

- Future of Cooking with Nanotechnology: How Smart Kitchen Technology Is Transforming Modern Kitchens

- The Hidden Genius Behind Your Devices – Gurtej Singh Sandhu’s Innovations That Fuel Our Digital World

- Hydrogen Fuel Cells — Powering a Cleaner Future of Energy & Mobility