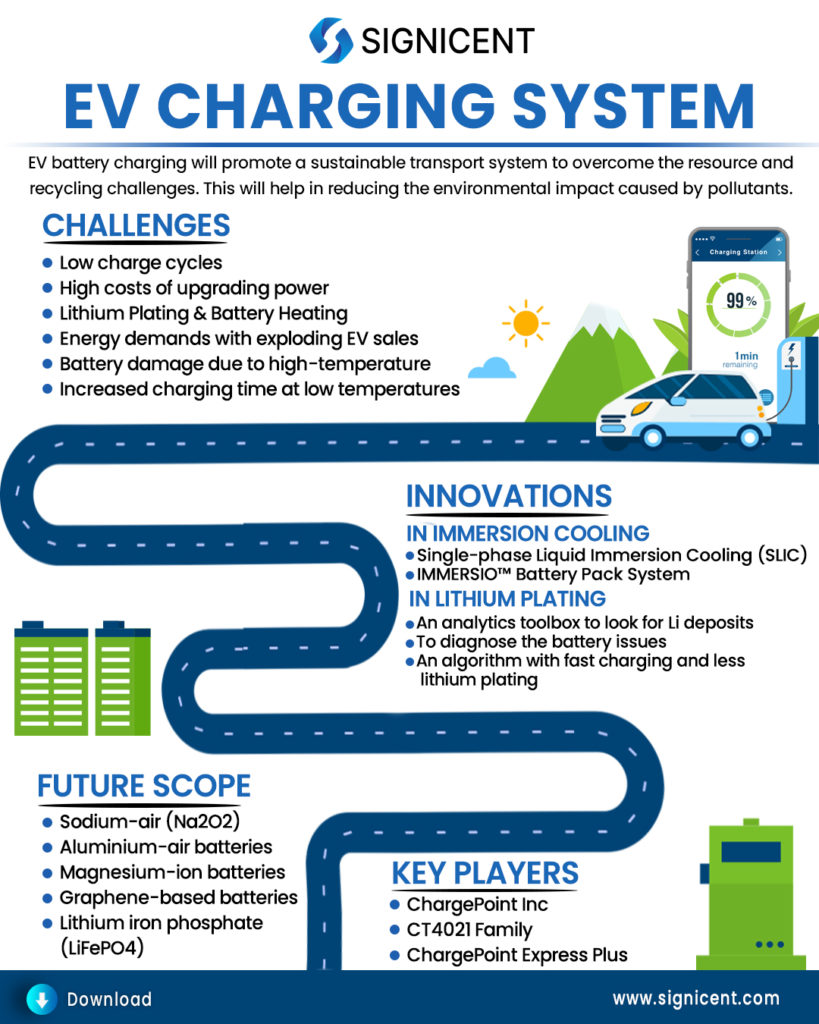

The electric vehicle (EV) charging system report will take you through technology scouting, innovations, key players, and market research. The report covers technological advancements to improve the EV ecosystem. Also, the identification of transformative market analysis in these technological areas from a global perspective has been touched upon.

Electric vehicles can help in reducing greenhouse gas emissions. This will promote a sustainable transport system. There are a few challenges that must be kept in vision, for instance, the full life cycle of electric vehicles. To meet the resource and recycling challenges created by electric vehicles, the circular economy approach for electric vehicles helps to reduce their environmental impact and ensure that trade-offs are minimized in achieving the necessary climate goals.

Associated Challenges in EV Battery Charging

- The charging time is greatly increased at low temperatures. When an EV battery was charged at 77 degrees, a DCFC charger might charge a battery to 80 percent capacity in 30 minutes. But at 32 degrees, the battery’s state of charge was 36 percent less after the same amount of time.

- Most electric vehicle batteries have an estimated 1500 to 2000 charge cycles, which is quite low.

- High costs of upgrading power grid to absorb EV charging load. By 2030, the high investments in grid upgrades may range from USD 1700 to USD 5800 per EV

- Possibility of battery damage due to high-temperature conditions. In temperatures of 95 degrees Fahrenheit and the air conditioning riving range decreases by 17%.

- Increase in energy demands with exploding EV sales. As EV sales continue to surge, the total charging-energy demand in China, Europe, and the United States will increase drastically.

- To fulfill the EV charging requirements, by 2030 USA needs to build approximately 380 EV charging ports that will need to be installed each day over the next nine years.

- Lithium Plating & Battery Heating. Lithium plating reduces the battery life drastically and limits the fast-charging capability. Poor thermal design of battery charging system leads to excessive heating.

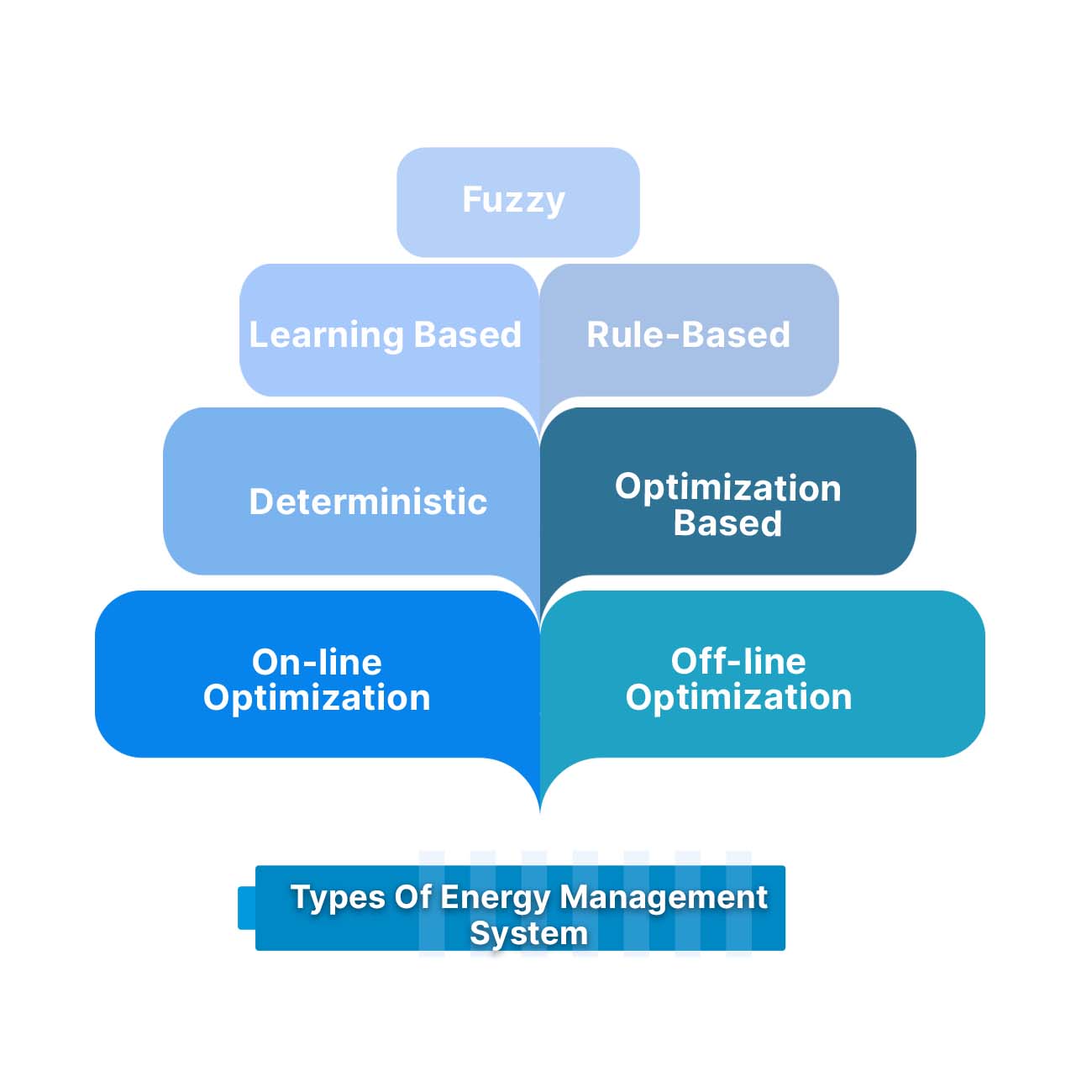

The EV charging system report herein sheds light on the types of energy management systems. Once we understand the structural architecture of the energy management system it becomes easy to find innovative approaches to find technological advancements to overcome the challenges.

High Heat Dissipation

During the charge and discharge cycles, lithium-ion battery cells generate a large amount of heat. The majority of this heat generation happens at a charge and discharge extremes, whereas, at a State of Charge (SOC) between 20 and 80 percent, there is usually little heat produced.

Although water-glycol cooling is most promising than the air-cooling system, it is still not an ideal system since it does not cool effectively enough to enable the rapid charging demands.

Immersive Cooling Technique

Recently, the immersive cooling technique is observed to do better than the currently used water-glycol system. In direct liquid immersion cooling of the battery, the battery cells are entirely immersed in a dielectric heat-transfer fluid (dielectric coolant). This cooling method is also called Single-phase Liquid Immersion Cooling (SLIC).

The dielectric coolant is typically circulated with a pump to ensure that it flows continuously throughout the device architecture and comes in continuous contact with all cell walls, tabs, and electrical wiring within the battery module. Direct coolant flow absorbs the heat produced by the cells by direct conduction.

It is then transferred to a heat transfer system such as a radiator or heat exchanger to transfer the heat energy to the atmosphere. If the heat load is sufficiently low, battery module cell walls can passively cool it utilizing convective airflow. Full immersion of battery cells also ensures the highest thermal contact and consistency. The figure given shows the Immersion Cooling Mechanism.

IMMERSIO™ Battery Pack System

XING Mobility has developed this battery pack that directly submerges lithium-ion battery cells in a non-conductive liquid coolant to efficiently distribute heat and homogeneity between the battery cells’ temperatures.

By 100% immersing lithium-ion battery cells in self-cooling, non-conductive fluid, XING Mobility’s superior cooling technology achieves extremely high power output and charge rates while remaining lightweight. Built from a unique micro module, the XING Mobility’s battery pack is stacked in a Lego-like fashion to meet diverse size and shape requirements without custom development, making it fast to deploy and easy to install.

Advantages of Immersion Cooling

- Superior heat transfer performance and battery pack temperature uniformity

- Longer battery life with Improved battery thermal control

- High power density

- The dielectric fluid is fully biodegradable and non-toxic & does not hamper battery recycling.

- Allows XFC (Extra-Fast Charging) charging in under 10 minutes (typical charge is 10 – 80% SoC), and Improved heat-transfer performance by a factor of 20 etc

Conclusion

Immersed-cooled batteries showed better results as they reduced battery peak temperature by 5% versus water glycol systems. Although the immersion cooling technology shows promise of technically excellent performance, due to the increased weight and cost compared to currently used methods, it might be difficult for immersion cooling to reach mass production in the automotive industry. Efforts to make this technology more advanced and efficient are hot research topics worldwide.

Lithium Plating Challenges

This section of the EV charging system report discusses the challenges associated with lithium plating and innovative solutions to overcome these challenges.

Electrochemical plating of Li metal in some cases forms lithium dendrite, which penetrates the separator and causes internal short. Li plating can cause the dangerous failure of the battery or, at a minimum, the loss of capacity over the lifetime of the battery. If the dendrites puncture the separator and make contact with the cathode, the battery will detroit.

Innovative Solution

The most common method to detect Li plating is to open the cell after cycling and look for Li deposits. Purdue University researchers have developed an analytics toolbox that allows battery developers to diagnose the issues with the batteries as they are operating, without having to dissect them.

They have developed an algorithm which would allow faster charging with less lithium plating with the goal to somehow integrate this algorithm with o experimental lab to create a system that could monitor lithium plating in real-time. With the help of three main observables a battery is operating: voltage, time, and temperature were translated into three quantifiable parameters: plating period, plating power, and plating energy. These quantifiers apply at any operating condition, on any size battery.

By plotting these three parameters on a graph an area was obtained(blue region in fig.2), in which the conditions are just right for lithium plating to occur. Which helps in detecting the possible zones for plating and optimum working conditions of batteries to prevent plating.

Conclusions

- Optimizing the working range with the help of an algorithm will help in preventing and early detection of lithium plating.

- Technologies to completely prevent Lithium-Ion batteries from degrading still have not been completely developed yet, although there are some methods such as early detection, and the use of silicon-dominated anodes which can reduce the plating rate.

Norway is the only country that appears to be truly on track to meet its EV goal. If Norway continues to grow at its current rate, it could achieve its 100% EV share goal in 2025. The Netherlands is experiencing increased growth after fluctuations from 2014 to 2017 due to a restructuring of its incentive program.

Futuristic Approach for EV Battery

Lithium iron phosphate (LiFePO4), this kind of battery provides an energy density of approximately 220 Wh/L, great durability and tolerates high temperatures. MIT researchers have managed to reduce its weight and they have developed a prototype cell that can be completely charged in just 10-20 s, a reduced time compared with the necessary 6 min.

Aluminum-air, batteries that are developed with such technology produces electricity from the reaction of oxygen with aluminum. This type of battery reaches a very large density, 6.2 KWh/L, which allows obtaining a high autonomy (up to 1600 Km). Aluminum-air batteries have the advantages that they are recyclable.

Graphene-based batteries have the ability they barely heat, enabling fast or ultra-fast charges without significant power losses due to heat. Graphenano, a Spanish company, has created a graphene battery that, added to a GTA Spano vehicle (900 hp), has been able to travel 800 km. In a high-power plug, this battery could be charged in only 5 min. This kind of battery is in an early phase of development.

Magnesium-ion, batteries change the use of lithium over magnesium, capabilities to store more than double the charge and increase its stability. It is expected that this type of battery can have a 6.2 KWh/L energy density, which is 8.5 times more than the best-known lithium batteries. Advanced Research Project Agency-Energy, Toyota and NASA are investigating this type of battery.

Sodium-air (Na2O2), the company BASF created a Sodium-air battery with an energy density of 4.5 KWh/L. In electric vehicles, these types of batteries can provide 13 times more autonomy of the current than the well-known lithium batteries.

Lithium-metal, in these batteries, graphite-anode is replaced by a fine lithium-metal layer. This kind of battery is able to store double the power of a traditional lithium battery. Sloid Energy System, an MIT startup, deployed this type of battery in drones, and it is expected that they can be included in EVs. Lithium-metal batteries have a high Coulombic efficiency (above 99.1%), withstanding more than 6000 charging cycles.

These technologies seem to increase the autonomy of EVs and considerably reduce the time required for a complete charge.

Market Demographics for EV

This section of the EV charging system report discusses the market trends, and dynamics, regarding electric vehicles.

EV charging market forecast: Estimated 25 million EVs on the road in China by 2030. Based on government policies, and nearly 3 million public charging points by the same year.

The tariff for public charging stations was capped at 15% of the average cost of supply in India. The government’s demand for incentives under the Faster Adoption and Manufacturing of (Hybrid) and Electric Vehicles (FAME)-II Scheme, as well as different tax breaks under state EV policies.

The Australian Electric Vehicle Charging Stations market is anticipated to grow at a CAGR of 14.53% during the forecast period of 2019-2024.

The United States electric vehicle (EV) charging equipment market is expected to register a CAGR of more than 28% during the forecast period of 2022-2027.

Germany’s electric vehicle charging market is anticipated to grow at a CAGR of over 21.0% during the forecast period, 2019-2025

Key Players in EV Charging System

This section of the EV charging system report will walk you through the key players that are working in the electric vehicle industry.

Founded in 2007 ChargePoint has a network with more than 68,000 charging spots, with 1,500 of them being Level 3 DC Fast Charging units. ChargePoint is the world’s largest network of electric vehicle (EV) charging stations in North America and Europe. It operates the largest online network of independently owned EV charging stations operating in 14 countries.

It has high-power DC charging with battery packs from 200V to 1000V. Also, it has 24/7 station monitoring with Mobile App and In-Dash Integration.

2. CT4021 Family

The CT4021 is the latest generation of ChargePoint commercial charging stations. Refined yet rugged, these stations set the industry standard for functionality and aesthetics. It has dual-port bollard charging with a level 2 charging system. The maximum charging rate of 25 RPH (miles of Range Per Hour) with a 5.7″ colour LCD display.

3. ChargePoint Express Plus

The ChargePoint® Express Plus is a DC fast charging platform, that integrates software, services and modular hardware to provide the flexibility to scale to meet the current and future needs of all types of electric vehicles (EVs). It is capable of delivering up to 350 kW with dual and single charging ports. It offers connectivity of 4G LTE with GSM as a backup.

Recent Report

- GCCs in Asia: Powering the Next Era of Global Digital and Biotech Innovation

- How Today’s Lipstick Formulations Deliver Comfort, Color & Clean Beauty

- How EU Regulations Shape Product Safety, Sustainability and Business Compliance

- Transparent Solar Panels Powering Smart and Green Cities

- Future of Cooking with Nanotechnology: How Smart Kitchen Technology Is Transforming Modern Kitchens